1. Introduction

In this comprehensive guide, we will explore the common issues faced with EPRV Series small worm gearboxes and how to troubleshoot them effectively. Whether you are a beginner or an experienced professional, understanding the troubleshooting process is essential for maintaining optimal performance and extending the lifespan of your gearboxes.

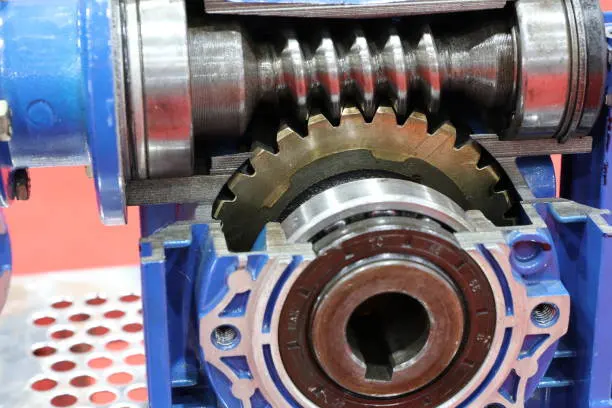

2. Understanding EPRV Series Small Worm Gearboxes

Before diving into the troubleshooting process, let’s first familiarize ourselves with the key components and functionality of EPRV Series small worm gearboxes. These gearboxes are specifically designed for applications requiring high torque and low speed, making them ideal for various industries such as equipment, food, car washing, packaging, and automation.

3. Common Issues and Troubleshooting Solutions

3.1 Overheating

One common issue that may arise with EPRV Series small worm gearboxes is overheating. This can be caused by various factors, including excessive load, inadequate lubrication, or improper installation. To troubleshoot this issue, follow these steps:

- Check the load on the gearbox and ensure it is within the recommended limits.

- Inspect the lubrication system and ensure it is functioning properly. If needed, replenish or replace the lubricant.

- Verify that the gearbox is installed correctly, with proper alignment and clearance.

3.2 Abnormal Noise

Another common issue is the presence of abnormal noise during gearbox operation. This can be indicative of worn-out gears, misalignment, or insufficient lubrication. To troubleshoot this issue, follow these steps:

- Inspect the gears for signs of wear or damage. Replace any faulty gears.

- Check the alignment of the gearbox components and adjust if necessary.

- Ensure that the gearbox is properly lubricated with the recommended type and quantity of lubricant.

3.3 Leakage

Leakage of lubricant or other fluids from the gearbox is a common issue that needs to be addressed promptly. To troubleshoot this issue, follow these steps:

- Inspect all seals and gaskets for signs of damage. Replace any faulty seals or gaskets.

- Check the tightness of all fasteners and bolts. Tighten if necessary.

- Ensure that the gearbox is properly sealed to prevent any leakage.

4. Importance of Electric Motors for Gearboxes

Electric motors play a crucial role in the operation of gearboxes, providing the necessary power to drive the gears and transmit motion. The relationship between gearboxes and electric motors is symbiotic, as each component relies on the other for optimum performance. Gearboxes amplify the torque provided by electric motors, enabling them to handle heavy loads and operate at lower speeds. Conversely, electric motors provide the power required for gearboxes to function effectively. At our company, we offer a wide range of electric motors that are perfectly matched with our gearboxes, ensuring seamless compatibility and superior performance.

Elektromotoren zu verkaufen

We are proud to offer a comprehensive selection of electric motors for sale. Our motors are designed to complement our gearboxes, providing the perfect combination for various applications. With our high-quality products and competitive prices, we strive to exceed customer expectations and deliver exceptional value. Explore our range of electric motors today and experience the seamless integration with our gearboxes.

Über uns

RP Techniek BV is the Netherlands sales agent of Ever-power Group. As a comprehensive transmission equipment manufacturer, we specialize in the research, development, manufacturing, and sales of speed reducers. With over 25 years of experience, we have established a strong presence in the European and American markets, serving customers with unrivaled quality, competitive prices, and excellent customer service. Our state-of-the-art production facilities and dedicated team ensure the highest standards of production and the delivery of reliable and efficient gearboxes. Our gearboxes find applications across various industries, including equipment, food, car washing, packaging, transmission, automation, and solar energy. We invite customers to explore our products and contact us for any inquiries or purchases.

Q&A

Q1: What maintenance practices can help extend the lifespan of EPRV Series small worm gearboxes?

A1: Regular lubrication, proper alignment, and periodic inspection of gears and seals can significantly prolong the lifespan of EPRV Series small worm gearboxes.

Q2: Can EPRV Series small worm gearboxes handle high torque applications?

A2: Yes, EPRV Series small worm gearboxes are specifically designed to handle high torque requirements, making them suitable for various industries.

Q3: What lubricant should be used for EPRV Series small worm gearboxes?

A3: It is recommended to use a high-quality, synthetic lubricant specifically designed for worm gear applications to ensure optimal performance and longevity.

Q4: Can EPRV Series small worm gearboxes be customized for specific applications?

A4: Yes, our company offers customization options to tailor EPRV Series small worm gearboxes to meet specific customer requirements, including gear ratio, input/output shaft size, and mounting options.

Q5: How can I purchase EPRV Series small worm gearboxes?

A5: To purchase EPRV Series small worm gearboxes, please contact our sales team or visit our website for more information.

Bearbeitet von: Zqq.