The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Labeling Machines

The worm gear in labeling machines is an essential component designed for precision and efficiency. This gear type allows for smooth and controlled motion, making it ideal for the fast-paced environment of labeling equipment. The worm gear in labeling equipment ensures that labels are applied accurately, enhancing productivity and reducing waste. In packaging, the labeling machine worm gear uses its unique design to manage torque effectively, ensuring that labels are securely affixed to products, ultimately improving the overall packaging process.

Specifications of Worm Gear in Labeling Machines

| Specification | Details |

|---|---|

| Gear Ratio | 10:1 |

| Material | Aluminum Alloy |

| Load Capacity | 2000 N |

| Efficiency | 85% |

| Operating Temperature | -20°C to 80°C |

| Lubrication Type | Grease |

Why Worm Gears are Suitable for Worm Gear in Labeling Machines

Worm gears are ideal for labeling machines due to their unique design and functionality. Here are some key reasons:

- High Torque Transmission: Worm gears provide excellent torque output, making them suitable for the heavy-duty requirements of labeling equipment.

- Compact Design: The compact nature of worm gear in labeling machines allows for space-efficient designs without compromising performance.

- Low Backlash: Labeling machine worm gear uses typically exhibit low backlash, ensuring precise movement and positioning.

- Durability: Worm gears are built to withstand wear, making them ideal for continuous operation in packaging applications.

How Worm Gears Work in Labeling Machines

Worm gears play a crucial role in the operation of labeling machines, providing precise control and efficiency. In labeling machines, worm gear in labeling machines ensures smooth rotation and reliable torque transmission. This unique gear mechanism allows for accurate positioning and movement of the labeling equipment, leading to consistent application of labels on various products. The labeling machine worm gear uses a threaded worm that engages with a gear wheel, delivering high reduction ratios and enabling better handling of high-speed operations. Additionally, the worm gear for packaging systems enhances the durability and stability of the machinery, making it an essential component in modern labeling equipment.

Manufacturing Process of Worm Gear in Labeling Machines

- Material Selection: The initial step in the manufacturing process of worm gear in labeling machines involves selecting high-quality materials. Typically, materials like alloy steel or brass are used due to their durability and resistance to wear. These materials ensure that the worm gear in labeling equipment operates smoothly and efficiently. Proper material selection is crucial, as it directly impacts the performance and lifespan of the labeling machine worm gear. Quality assurance tests are performed to ensure that the chosen materials meet industry standards.

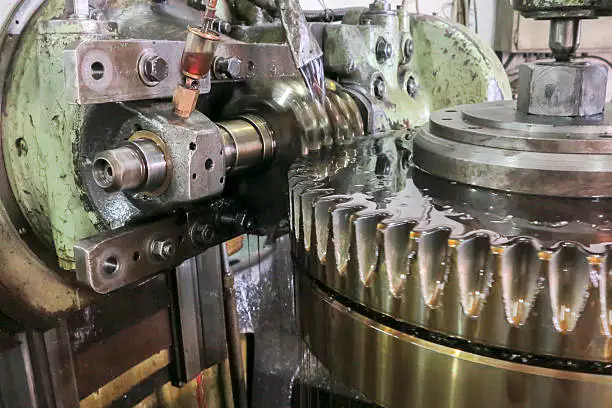

- Precision Machining: After material selection, the manufacturing process proceeds with precision machining of the worm gear. Using CNC machines, the shape and dimensions of the worm gear are crafted with utmost accuracy. This step is vital for ensuring that the worm gear for packaging fits perfectly with other components of the labeling machine. The precision achieved during this stage minimizes friction and enhances the overall efficiency of the labeling machine worm gear, contributing to better performance in labeling tasks.

- Heat Treatment: Following machining, heat treatment is applied to the worm gear in labeling machines to improve its hardness and strength. This process involves heating the gear to a specific temperature and then cooling it rapidly. Heat treatment not only enhances the wear resistance of the worm gear in labeling equipment but also helps in achieving the desired mechanical properties. This step is essential for ensuring that the worm gear withstands the rigorous demands of packaging operations.

- Finishing Processes: The final stage in the manufacturing process involves various finishing processes such as grinding and polishing. These processes enhance the surface quality of the worm gear in labeling machines, reducing friction and improving overall functionality. A well-finished worm gear for packaging ensures smooth operation within the labeling machine. Additional coatings may be applied for corrosion resistance, further extending the lifespan of the labeling machine worm gear.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for the Ever-power Group, positioning us as one of the top ten worm gear suppliers in the Netherlands.

Our company specializes in high-quality worm gears used in labeling machines, offering a range of products that stand out in the market:

- Exceptional Quality: Our worm gears are manufactured to meet rigorous quality standards, ensuring reliability and durability.

- Premium Materials: We use only the finest materials, which contribute to the overall performance and longevity of our products.

- Strong Expertise: With years of experience in the industry, we have built a reputation for excellence and innovation.

- Comprehensive Service: Our dedicated team provides outstanding customer support, ensuring that all client needs are met promptly.

Weitere Informationen

| Edited | Zqq |

|---|

Blogs aktualisiert

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...