The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Construction Machinery

The worm gear in construction machinery plays a crucial role in the efficient operation of various equipment. This specialized component provides high torque and precise movement, making it ideal for worm gear in construction equipment. Its unique design allows for compact configurations, essential for construction worm gear applications. A reliable worm gear for heavy construction ensures durability and longevity, which is vital in demanding environments. With a durable worm gear for construction, machinery can achieve optimal performance in worm gear in building machinery, enhancing productivity and safety on the job site.

Specifications of Worm Gear in Construction Machinery

| Specification | Details |

|---|---|

| Gear Ratio | 10:1 |

| Material | Alloy Steel |

| Load Capacity | 5000 kg |

| Efficiency | 85% |

| Operating Temperature | -20°C to 100°C |

| Dimensions | 200 mm x 150 mm x 100 mm |

Why Worm Gears are Suitable for Worm Gear in Construction Machinery

Worm gears are ideal for various worm gear in construction machinery applications due to their unique design and benefits:

- High Torque Transmission: Worm gears provide excellent torque output, making them perfect for worm gear in construction equipment.

- Space Efficiency: Their compact size allows for integration into various construction worm gear applications.

- Durability: A durable worm gear for construction ensures long-lasting performance under heavy loads.

- Low Backlash: This feature is crucial in worm gear for heavy construction machinery for precise movements.

- Versatility: Suitable for use in worm gear in building machinery across different construction tasks.

How Worm Gears Work in Construction Machinery

Worm gears are essential components in construction machinery, ensuring efficient power transmission and torque multiplication. In construction equipment, the worm gear’s unique design allows for high reduction ratios, making it ideal for heavy construction tasks. The construction worm gear applications include cranes, hoists, and other machinery that require precise movements and control. A durable worm gear for construction can withstand harsh working conditions, providing reliability and longevity. With a worm gear for heavy construction, operators can achieve smoother operations, reducing the risk of mechanical failures. This makes worm gears a fundamental part of building machinery, enhancing performance and safety on the job site.

Manufacturing Process of Worm Gear in Construction Machinery

- Material Selection: The production of worm gears for construction machinery begins with selecting the right material. High-quality steel or bronze is typically chosen for its strength and durability. These materials ensure that the worm gear in construction equipment can withstand heavy loads and resist wear and tear. The right material is critical for ensuring the longevity and reliability of worm gears in building machinery.

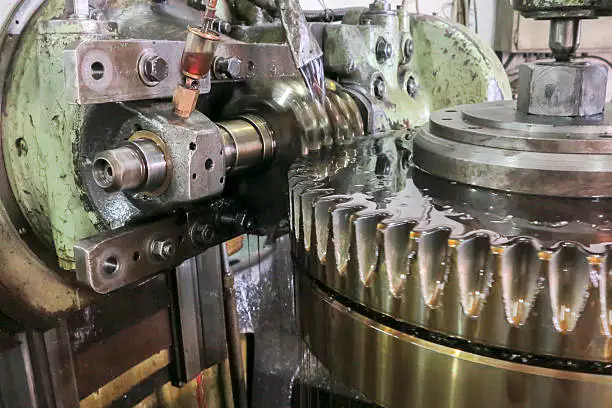

- Precision Machining: After material selection, precision machining is carried out to create worm gears for heavy construction. This process involves cutting, shaping, and finishing the gear to exact specifications. Advanced CNC machines are often used to achieve the desired dimensions and tolerances. The accuracy of this step is essential for the proper functioning of the worm gear in construction machinery, as it affects the gear's meshing and overall performance.

- Heat Treatment: Heat treatment is a crucial part of manufacturing durable worm gears for construction. This process enhances the hardness and strength of the gear, making it more resistant to wear and tear. By employing methods such as quenching and tempering, manufacturers ensure that the worm gear for construction equipment can handle the rigorous demands of heavy-duty applications, thus prolonging its service life.

- Surface Finishing: The final step in the manufacturing process involves surface finishing, which improves the gear's performance and lifespan. Techniques like grinding and coating are used to reduce friction and improve corrosion resistance. A well-finished worm gear in construction machinery operates more efficiently, which is vital for effective construction worm gear applications in various building projects.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands.

In the realm of Worm Gear in Construction Machinery, our offerings stand out for several reasons:

- Top-Quality Products: We provide worm gears that are manufactured with precision, ensuring durability and reliability in construction machinery.

- Exceptional Standards: Our products meet stringent quality standards, guaranteeing excellent performance in demanding environments.

- Strong Capabilities: With advanced technology and a skilled workforce, we are equipped to handle large-scale orders and specialized requests.

- Unmatched Service: Our customer support team is dedicated to providing personalized service, ensuring that our clients receive the best solutions tailored to their needs.

Weitere Informationen

| Edited | Zqq |

|---|

Blogs aktualisiert

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...