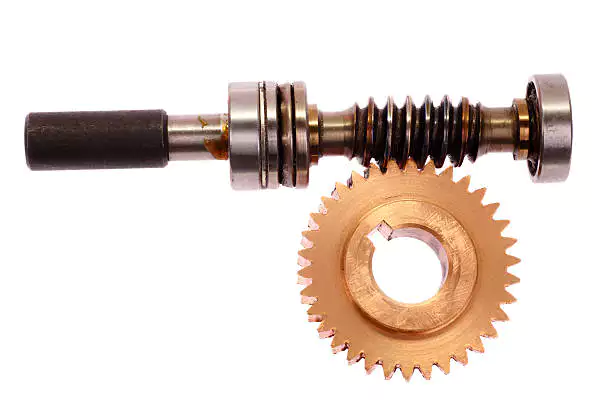

The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

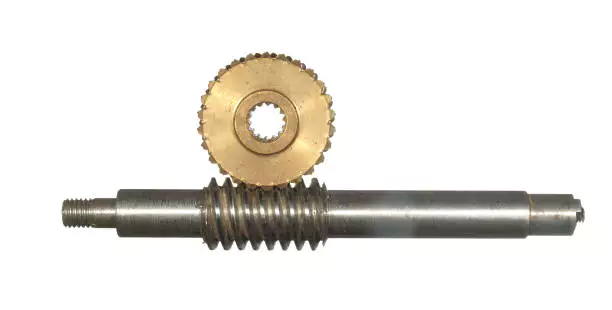

Worm Gear for Lift Mechanisms

The worm gear for lift mechanisms is a crucial component designed to ensure smooth and reliable operation in various lifting systems. This specialized worm gear in lift systems provides the necessary torque and control, making it ideal for applications such as elevators and vertical lift systems. With its compact design, the worm gear for elevator lifts enhances efficiency while minimizing space requirements. Its reliability in lift mechanism worm gear applications makes it a preferred choice for engineers looking to optimize performance in lifting technology.

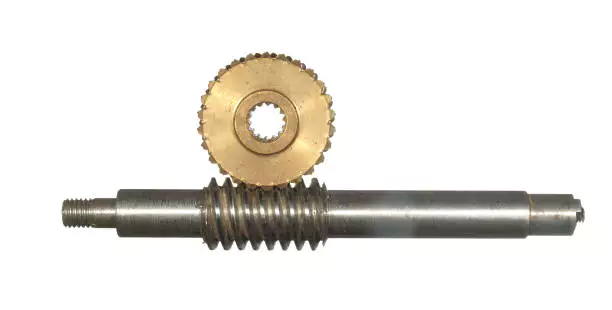

Specifications of Worm Gear for Lift Mechanisms

| Specification | Details |

|---|---|

| Gear Ratio | 20:1 |

| Material | Aluminum Alloy |

| Load Capacity | 500 kg |

| Efficiency | 85% |

| Operating Temperature | -20°C to 100°C |

| Gewicht | 2.5 kg |

Why Worm Gears are Suitable for Worm Gear for Lift Mechanisms

- Worm gears in lift systems provide high torque and load capacity, making them ideal for heavy-duty applications.

- The compact worm gear for lifts design allows for space-saving configurations, essential in various lift mechanism worm gear applications.

- Worm gear for elevator lifts ensures smooth operation and minimal noise, enhancing user experience.

- These gears offer a self-locking feature, which is crucial for safety in vertical lift systems.

- Overall, the efficiency and reliability of worm gear in lift systems make them a preferred choice for various lifting mechanisms.

How Worm Gears Work in Lift Mechanisms

The worm gear for lift mechanisms plays a vital role in ensuring smooth and efficient operations in various lift systems. In lift mechanism worm gear applications, the design allows for high torque transmission while maintaining compact dimensions. The worm gear in lift systems converts the rotational motion of the input shaft into linear movement, which is essential for elevating loads in elevator lifts. This unique gear configuration provides a self-locking feature, enhancing safety by preventing the lift from descending unexpectedly. Compact worm gear for lifts is particularly advantageous in vertical lift systems, where space is limited. Overall, the worm gear for elevator lifts is integral to the reliable performance of modern lifting solutions.

Manufacturing Process of Worm Gear for Lift Mechanisms

- Material Selection: The manufacturing of worm gears for lift mechanisms begins with the careful selection of high-quality materials. Common choices include alloy steels and brass, as they provide excellent durability and resistance to wear. The right material ensures that the worm gear in lift systems can withstand the heavy loads and stresses encountered during operation. This step is critical for applications such as worm gear for elevator lifts, where reliability and safety are paramount.

- Precision Machining: Once the materials are selected, precision machining is employed to shape the worm gear for lift mechanisms. Advanced CNC machines are utilized to create the intricate profiles and threads required for optimal performance. This machining process ensures that the worm gear in vertical lift systems fits perfectly with the mating components, minimizing friction and enhancing efficiency. High precision is vital to meet the stringent standards of lift mechanism worm gear applications.

- Surface Treatment: After machining, surface treatment is applied to the worm gears. This may include processes such as hardening, coating, or grinding to enhance wear resistance and reduce friction. Surface treatment is essential for worm gears used in lift systems, as it prolongs their lifespan and ensures smooth operation. A well-treated worm gear for elevator lifts can significantly improve the overall functionality and safety of the lifting system.

- Quality Control: Quality control is a crucial phase in the manufacturing process of worm gears for lift mechanisms. Each gear undergoes rigorous testing to verify its strength, precision, and overall performance. This includes checks for dimensional accuracy and load-bearing capacity. Ensuring that the worm gear in lift systems meets industry standards is vital to prevent failures in lift mechanism worm gear applications and to guarantee user safety in vertical lift systems.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country.

Our company specializes in providing high-quality worm gears for lift mechanisms, and we ensure that our products meet the highest standards:

- Superior Quality: Our worm gears are manufactured using premium materials, guaranteeing durability and exceptional performance.

- Unmatched Expertise: With years of experience in the industry, we have the technical know-how to cater to diverse applications.

- Comprehensive Service: We offer complete support, from product selection to after-sales service, ensuring customer satisfaction at every step.

- Innovative Solutions: Our commitment to innovation enables us to deliver customized solutions that meet specific client needs.

Weitere Informationen

| Edited | Zqq |

|---|

Blogs aktualisiert

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...