The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

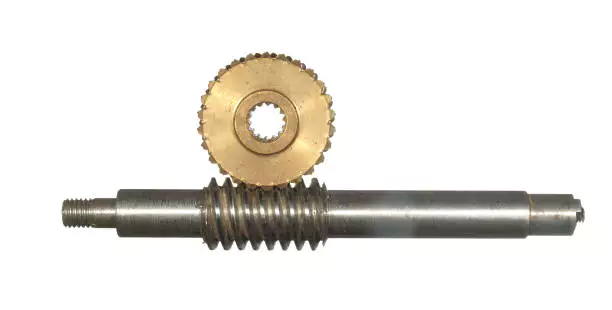

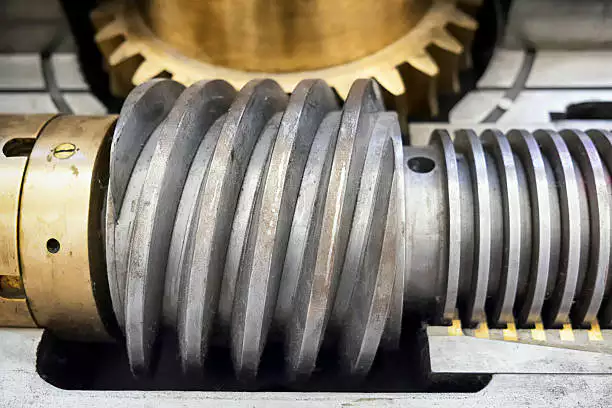

Spiral Worm Gear

The Spiral Worm Gear is an essential mechanical component used for precise motion transmission in various applications. Made from high-quality steel or aluminum, it ensures durability and efficiency. The design of the Spiral Worm Gear allows for smooth operation, providing excellent torque and speed reduction, making it ideal for gearboxes and machinery.

Details of Spiral Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | Up to 100:1 |

| Material | Aluminum Alloy |

| Max Load Capacity | 500 Nm |

| Efficiency | 85% - 95% |

| Operating Temperature | -20°C to 100°C |

| Lubrication Type | Oil Bath |

Key Features of Spiral Worm Gear

- Hohe Effizienz: Spiral Worm Gears are designed to provide superior efficiency in power transmission. The unique angle of the teeth allows for smoother engagement and reduced friction, resulting in less energy loss during operation.

- Compact Design: The design of Spiral Worm Gears allows for a more compact arrangement compared to traditional gear systems. This makes them ideal for applications where space is limited while maintaining performance.

- Rauschunterdrückung: The spiral tooth configuration significantly minimizes noise and vibration. This makes Spiral Worm Gears suitable for applications where quiet operation is essential, such as in automotive or precision machinery.

Applications of Spiral Worm Gear in Modern Machinery

Spiral Worm Gears are essential components in various industrial applications due to their ability to provide high torque in a compact design. These gears are commonly used in automotive transmissions, conveyor systems, and lifting equipment. The unique design of the Spiral Worm Gear allows for smooth operation and efficient power transmission. Their durability and reliability make them ideal for heavy-duty applications, where precision and strength are crucial. Integrating Spiral Worm Gears into machinery not only enhances performance but also extends service life, making them a preferred choice in numerous engineering fields.

Manufacturing Process of Spiral Worm Gear

The manufacturing process of the Spiral Worm Gear involves several intricate steps to ensure precision and quality in the final product.

- Material Selection: The first step in manufacturing Spiral Worm Gears is selecting appropriate materials. High-quality steel or bronze is commonly used due to their excellent wear resistance and durability. The right material ensures that the Spiral Worm Gear can withstand high loads and operating conditions while maintaining its structural integrity over time.

- Machining the Worm Shaft: The next step involves machining the worm shaft, which is a critical component of the Spiral Worm Gear. This process typically uses computer numerical control (CNC) machines to achieve precise dimensions and tolerances. The design of the worm shaft directly affects the efficiency and performance of the gear, so accuracy is essential during this phase.

- Shaping the Worm Wheel: After the worm shaft is completed, the worm wheel is shaped to match the specifications of the Spiral Worm Gear. This involves processes such as hobbing or shaping to create the teeth on the wheel. Proper tooth geometry is vital for smooth operation and minimal backlash in the gear system.

- Heat Treatment: Once the components are machined, they undergo heat treatment to enhance their mechanical properties. This process improves hardness and wear resistance, ensuring the longevity of the Spiral Worm Gear. Heat treatment also helps to relieve any residual stresses from the machining process, reducing the risk of deformation during operation.

- Assembly and Testing: Finally, the Spiral Worm Gear components are assembled, and the entire system is tested for functionality and performance. This includes checking for proper alignment, backlash, and noise levels during operation. Thorough testing guarantees that the Spiral Worm Gear meets industry standards and is ready for use in various applications.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands.

Our product offerings include:

- Spiral Worm Gears: Designed for high efficiency and smooth operation.

- Top-Quality Materials: Our products are made from premium materials ensuring durability.

- Exceptional Performance: We focus on delivering products that meet stringent quality standards.

- Strong Industry Presence: With years of experience, we have established a solid reputation in the market.

- Comprehensive Customer Service: Our dedicated team provides personalized support and expertise.

At RP Techniek BV, we pride ourselves on our commitment to quality and customer satisfaction, ensuring you receive the best products and service available.

Weitere Informationen

| Edited | Zqq |

|---|

Blogs aktualisiert

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...