The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

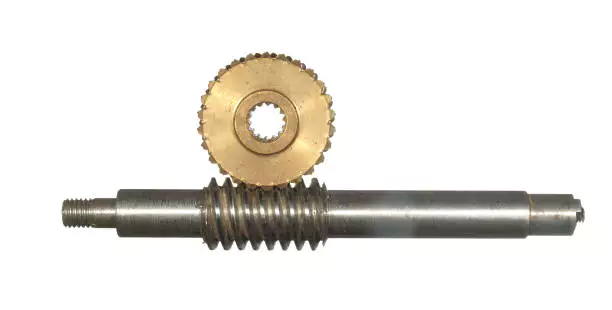

Large Worm Gear

The large worm gear is an essential mechanical component designed for transmitting torque and reducing speed in various applications. Made from high-quality materials such as steel or aluminum, this large worm gear set ensures durability and efficiency. Its primary function is to enable smooth motion and precise control in machinery, making it invaluable in industrial settings.

Details of Large Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 10:1 |

| Material | Alloy Steel |

| Diameter | 200 mm |

| Length | 150 mm |

| Gewicht | 5 kg |

| Efficiency | 85% |

Features of Large Worm Gear

- High Torque Transmission: The large worm gear design enables efficient torque conversion, making it ideal for heavy-duty applications where strength and reliability are paramount.

- Kompakte Größe: Despite its robust performance, the large worm gear set offers a compact solution, allowing for space-saving installations in various machinery.

- Smooth Operation: The unique design of the large worm gear reduces noise and vibration, ensuring smoother operation, which is crucial for precision tasks.

- Durability: Constructed from high-quality materials, the large worm gear is built to withstand wear and tear, ensuring longevity and consistent performance over time.

Understanding the Functionality of Large Worm Gears

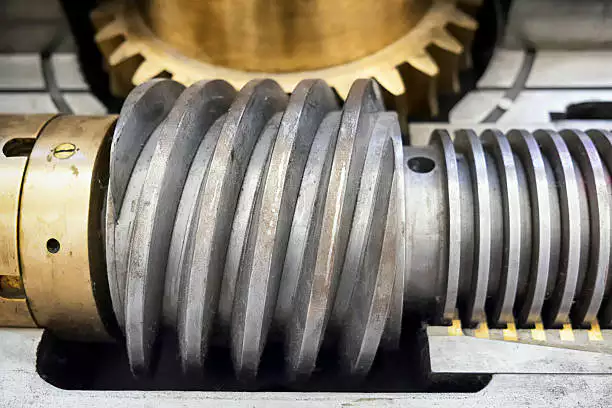

The large worm gear is a crucial component in various mechanical systems, providing efficient torque conversion and motion transfer. When paired with a large worm gear set, it allows for a significant reduction in speed while increasing torque output. This unique configuration enables precise control in applications such as conveyor systems and heavy machinery. The design of the large worm gear ensures smooth operation while minimizing backlash, making it ideal for high-load scenarios. For a visual representation of this component, see the image below.

Manufacturing Process of Large Worm Gear

- Material Selection: The manufacturing of a large worm gear begins with the careful selection of materials. High-quality steel or bronze is commonly used to ensure durability and optimal performance. The choice of material affects the gear's strength, wear resistance, and overall lifespan. Proper material selection is crucial for the large worm gear set, as it directly impacts its efficiency and functionality in various applications.

- Precision Machining: Once the materials are selected, the large worm gear undergoes precision machining. This involves using CNC machines to create the intricate profiles of the gear teeth. The machining process ensures that the large worm gear is manufactured to exact specifications, which is vital for proper meshing with the worm shaft. High precision in this stage guarantees smoother operation and enhances the performance of the large worm gear set.

- Heat Treatment: After machining, the large worm gear typically undergoes heat treatment to improve its hardness and strength. This process involves heating the gear to a specific temperature and then cooling it rapidly, which alters the material's microstructure. Heat treatment is essential to increase the wear resistance of the large worm gear, making it suitable for high-load applications while extending its operational life.

- Quality Control: Quality control is a critical step in the manufacturing process of the large worm gear. Each gear is thoroughly inspected for dimensional accuracy, surface finish, and overall integrity. This includes testing for any defects that could affect the performance of the large worm gear set. Ensuring that each component meets stringent quality standards is crucial for reliable operation in various machinery.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands. Our commitment to excellence and customer satisfaction sets us apart in the industry.

When it comes to Large Worm Gears, we offer:

- High Quality Products: Our worm gears are engineered with precision, ensuring durability and reliability in various applications.

- Exceptional Craftsmanship: We take pride in our manufacturing process, utilizing advanced technology and skilled personnel to maintain top-tier standards.

- Strong Expertise: With years of experience in the industry, our team is equipped to provide expert advice and solutions tailored to your needs.

- Outstanding Service: We prioritize customer support, ensuring timely delivery and assistance throughout your purchasing journey.

Weitere Informationen

| Edited | Zqq |

|---|

Blogs aktualisiert

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...