As a crucial part of mechanical equipment, the gearbox’s lifespan and performance have a direct impact on the system’s overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run.

The Value of Lubricating Gearboxes

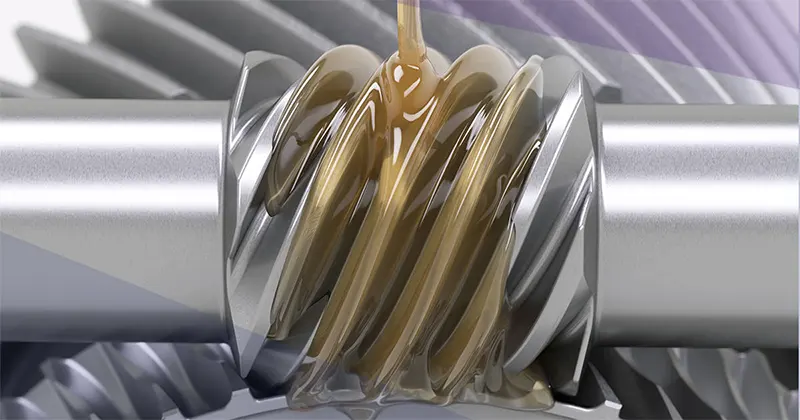

Reduce Wear and Friction

By creating a protective layer in the gearbox, lubricant lessens wear and friction by minimizing direct gear-to-gear contact. This increases transmission efficiency and prolongs the life of the gears.

Dissipation of Heat and Cooling

Because lubricants are good at absorbing and dissipating heat, they help keep gears from overheating and prevent material deformation and performance loss brought on by high temperatures.

Rust and Corrosion Prevention

Additives in the lubricant can prevent surface rust and corrosion of gears, especially in wet or corrosive environments, which is particularly important.

Gearbox Lubricant Selection

Type of Base Oil

According to the working conditions and environment of the gearbox, select the appropriate type of base oil. Mineral oils, synthetic oils, and semi-synthetic oils are common base oils; each type has unique benefits and drawbacks and should be chosen based on the circumstances.

Viscosity Grade

The viscosity of a lubricant directly affects its lubricating effect. Selecting the proper viscosity grade ensures that the lubricant will form an adequate film at the operating temperature of the gearbox, while avoiding energy loss due to high viscosity.

Additives

Additives in lubricating oil can improve its performance, such as anti-wear agents, extreme pressure agents, antioxidants, and rust inhibitors. The right combination of additives should be selected according to the specific needs of the gearbox.

Gearbox Lubrication Methods

Splash Lubrication

Splash lubrication is suitable for small and medium-sized gearboxes. The lubricating oil splashes through the rotation of the gears to form oil mist or oil droplets to lubricate the gears and bearings. This method is simple and reliable, but the oil level needs to be checked regularly.

Pressure Lubrication

Pressure lubrication uses an oil pump to deliver lubricating oil to various lubrication points in the gearbox, which is suitable for large or high-speed gearboxes. This method can provide stable lubrication, but the system is complex and the maintenance cost is high.

Oil Bath Lubrication

Oil bath lubrication is to immerse the gear part in the lubricating oil and bring the lubricating oil out through the rotation of the gear. This method is suitable for low-speed gearboxes with good lubrication effect, but attention should be paid to oil level control.

Gearbox Maintenance Measures

Regular Inspection

Regularly check the oil level, oil quality, and sealing condition of the gearbox to ensure the normal operation of the lubrication system. The inspection frequency should be determined according to the working conditions of the gearbox and the manufacturer’s recommendations.

Replace the Lubricant

Replace the lubricant regularly according to the service life of the lubricant and the working conditions. When replacing, the gearbox needs to be thoroughly cleaned to avoid the old oil residue affecting the performance of the new oil.

Cleaning and Dust Prevention

Keep the outside of the gearbox clean to prevent dust and impurities from entering the lubrication system. Regularly clean the vents and filters to ensure the smooth flow of the lubrication system.

Vibration and Noise Monitoring

Detect abnormalities in the gearbox in time through vibration and noise monitoring. Abnormal vibration and noise may signal gear wear, bearing damage, or poor lubrication and need to be dealt with promptly.

Common Problems and Solutions

Unzureichende Schmierung

Insufficient lubrication can lead to increased gear wear or even galling. The solution is to check the oil level and oil quality to ensure that the lubrication system operates normally and replenish or replace the lubricant if necessary.

Excessive Lubrication

Excessive lubrication will increase the energy loss and cause the oil temperature to rise. The solution is to adjust the oil level to avoid excessive lubrication and to check whether there is any leakage in the lubrication system.

Oil Contamination

Oil contamination will reduce the lubrication effect and lead to gearbox failure. The solution is to change the lubricant regularly, clean the gearbox, and check the condition of seals and filters.

Lubrication and maintenance of the gearbox are the keys to ensuring its long-term stable operation. By choosing the right lubricant, using appropriate lubrication methods, and implementing regular maintenance measures, the service life of the gearbox can be effectively extended, thereby improving the operating efficiency of the equipment. RP Techniek BV specializes in providing high-performance Getriebe solutions for various industrial, marine, and energy applications. Our products have excellent reliability, high performance, and long service life to meet the various needs of our customers.