In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Details

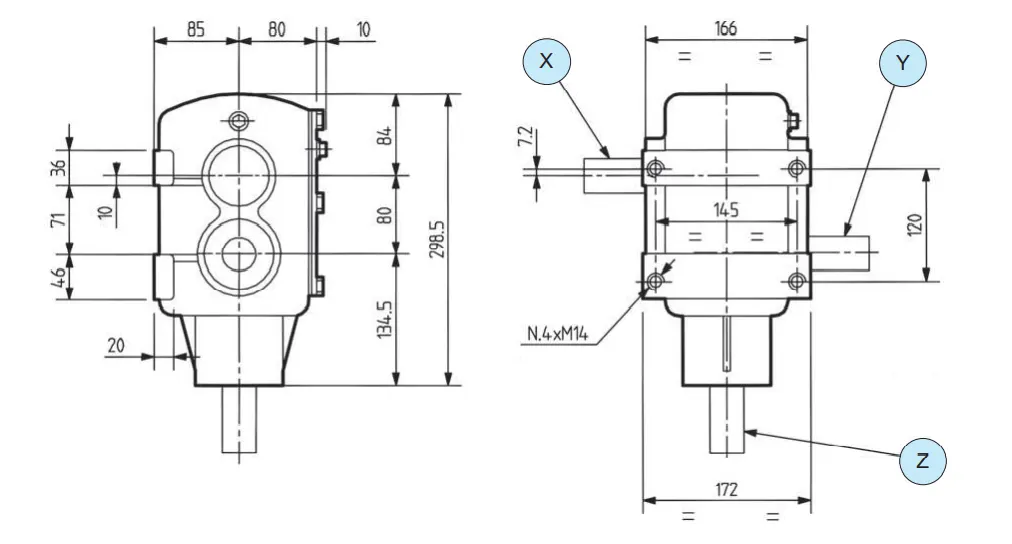

| i | 5.67 |

| N1[rpm] | 540 |

| P1[kW] | 23.5 |

| M2[Nm] | - |

Shaft X |

1'' 3/8 Z6 |

Shaft Y |

1'' 3/8 Z6 |

Shaft Z |

1'' 3/8 Z6 |

| Input | Z |

Einführung

Manure spreaders are an essential tool for farmers who want to spread manure over their fields to fertilize crops. The gearbox of a manure spreader is a critical component that drives the spreader mechanism. When the gearbox fails, it can cause the spreader to stop working, resulting in lost time and income for farmers. The Comer Code N-2A gearbox is a popular component for manure spreaders, but it is sometimes necessary to replace it. In this article, we will explore the replacement of the Comer Code N-2A gearbox in manure spreaders.

Understanding Manure Spreaders Gearboxes

Manure spreader gearboxes are designed to transfer power from the tractor to the spreader's beaters or apron. They are usually mounted under the spreader and come in different sizes and ratios to match the tractor's power output. The Comer Code N-2A gearbox is a popular component that can be found in many manure spreaders. It has a cast iron housing and an input shaft that is splined to accept a PTO shaft from the tractor. The output shaft usually drives a sprocket or pulley that drives the spreader mechanism.

Choosing a Replacement Gearbox

When choosing a replacement gearbox for a manure spreader, there are several factors to consider. One important factor is the gearbox's capacity. It needs to be able to handle the power output of the tractor and the size of the spreader. Another factor to consider is the gear ratio. The gear ratio determines how much torque is delivered to the spreader's mechanism. A higher gear ratio will deliver more torque, which can be useful for spreading heavy or sticky manure. Finally, it's important to choose a replacement gearbox that is compatible with the spreader's other components, such as the sprocket or pulley that drives the mechanism.

Installation of Replacement Gearbox

Installing a replacement gearbox in a manure spreader can be a complex process that requires some mechanical knowledge. The first step is to remove the old gearbox from the spreader. This may involve disconnecting the input and output shafts and removing any mounting bolts or brackets. Once the old gearbox is removed, the new gearbox can be installed. This may involve aligning the input and output shafts and mounting the gearbox to the spreader's frame. Finally, the new gearbox should be tested to ensure that it is working correctly.

Maintenance of Manure Spreaders Gearboxes

Manure spreader gearboxes require regular maintenance to ensure that they continue to function properly. This includes checking the gearbox's oil level and changing the oil as needed. It also involves inspecting the gearbox's internal components for wear and replacing any parts that are damaged or worn out. Finally, it's important to keep the gearbox clean and free of debris that could cause damage or wear to its components.

The Comer Code N-2A gearbox is a popular component for manure spreaders, but it may need to be replaced due to wear, damage, or the need for an upgrade. When choosing a replacement gearbox, it's important to consider factors such as capacity, gear ratio, and compatibility with other components. Installing a replacement gearbox can be a complex process that requires some mechanical knowledge, and regular maintenance is necessary to ensure that the gearbox continues to function properly.

Why Choose Our Agricultural Gearboxes?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We specialize in providing high-quality agricultural gearboxes for various types of farm machinery. Our Manure Spreaders Gearboxes - Replacement of Comer Code N-2A is a unique product that highlights our commitment to excellence in product quality and customer service.

Our gearboxes are engineered to withstand the toughest conditions and provide reliable performance over a long service life. We use only the highest quality materials and the latest manufacturing techniques to ensure that our products meet or exceed industry standards.

In addition to our gearboxes, we also offer a wide range of other agricultural machinery parts and transmission components. Whether you need replacement parts for your existing machinery or want to upgrade to the latest technology, we have the expertise and resources to help you find the right solution.

With over 20 years of experience in the industry, we have built a reputation for delivering high-quality products and exceptional customer service. Our team of experienced professionals is dedicated to helping you find the right solution for your specific needs.

Choose RP Techniek BV for all your agricultural gearbox needs, and experience the difference in quality and service that sets us apart from the competition.

PTO Shafts for Agricultural Gearboxes

PTO shafts play a crucial role in the operation of agricultural gearboxes, particularly when it comes to the replacement of Comer Code N-2A in Manure Spreaders Gearboxes. These shafts are an essential component that connects the power source, such as a tractor, to the agricultural gearbox, enabling the transfer of power and torque.

At our company, we understand the importance of reliable and high-quality PTO shafts for agricultural equipment. We offer a wide range of agricultural drive shafts for sale, including the specific PTO shafts required for Comer Code N-2A replacement in Manure Spreaders Gearboxes. Our shafts are designed to meet the demanding needs of agricultural applications, ensuring efficient power transmission and enhanced durability.

To give you a visual representation, please find the image below showcasing one of our PTO drive shafts:

With our extensive selection of PTO shafts and commitment to quality, we are dedicated to meeting the needs of the agricultural industry and providing reliable solutions for efficient power transmission.

Weitere Informationen

| Editor | Zqq |

|---|

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...