In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

WPWKS Universal Speed Cast Iron Worm Gearbox

The WPWKS Universal Speed Cast Iron Worm Gear Reducer, with its model number WPWKS, is a worm reducer that is commonly used in various industries. It is known for its high efficiency, stable operation, and long service life, making it suitable for conveyor belts, mixers, packaging machinery and other similar equipment. This gear reducer can handle heavy loads with a maximum output torque of 18000Nm.

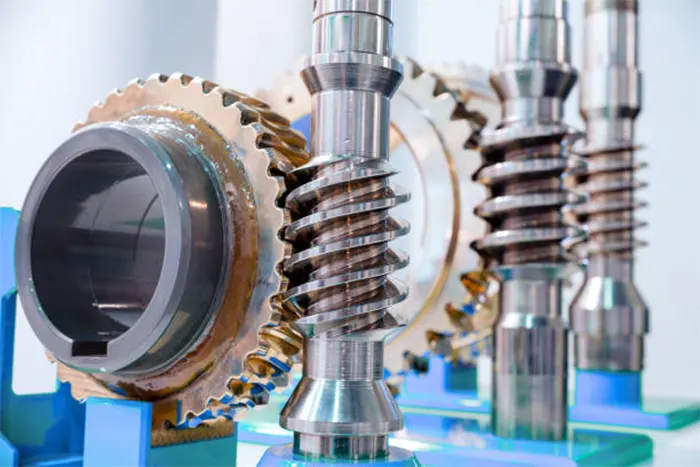

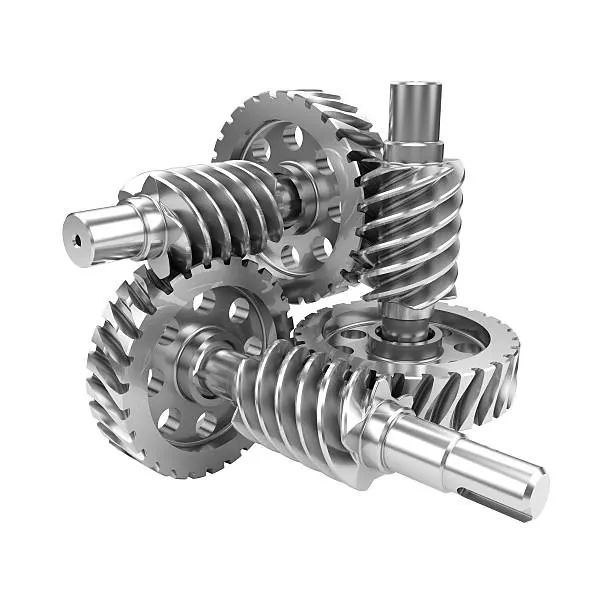

Structure Composition of Cast Iron Worm Gearbox

The WPWKS Universal Speed Cast Iron Worm Gear Reducer is composed of a worm gear set, a shell, a bearing, a sealing ring, a lubricant system, and an output shaft. The shell is made of high-strength cast iron, which provides excellent protection for the internal components of the gearbox. The gearbox is designed with a lubricant system ensuring that it remains sufficiently lubricated and cooled during operation.

Features of WPWKS Universal Speed Cast Iron Worm Reducer

- This product has a high transmission efficiency, up to 89%.

- The compact structure makes it easy to install and maintain.

- The worm gear set is made of high-quality materials and has a long service life.

- The high-strength cast iron shell makes it suitable for use in harsh environments.

Specifications of WPWKS Universal Speed Cast Iron Worm Gear Reducer

Installation and Use of WPWKS Universal Speed Cast Iron Worm Reducer

When installing WPWKS Universal Speed Cast Iron Worm Gear Reducer, please pay attention to the following:

- The reducer must be installed on a flat and solid foundation, and the base bolts must be tightened and shock-proofed.

- The input and output shafts of the reducer and the working machine must be accurately aligned with each other after installation.

- The tolerance size of the outer diameter of the input and output shafts of the reducer is made according to h6, and the inner holes of transmission parts such as couplings, pulleys, and sprockets that match it must be configured according to appropriate tolerance sizes to avoid damaging the bearings due to excessive assembly and affecting normal power transmission.

- When installing transmission parts such as sprockets and gears on the shaft, try to get them as close as possible to the bearings to reduce the bending stress of the shaft.

- When assembling the motor on the WPD reducer, apply grease to the hole wall and keyway of the worm head to avoid over-tightening and prevent the shaft hole from rusting over time.

When using WPWKS Universal Speed Cast Iron Worm Gear Reducer, please pay attention to the following:

- Check whether the reducer model structure, center distance specifications, transmission ratio, input shaft connection method, output shaft structure, input shaft output shaft axis orientation, and rotation direction meet the requirements before use.

- Inject the appropriate brand and grade of lubricant according to the requirements specified in the sample "Selection and Use of Lubricating Oil". After refueling, tighten the top breather, remove the small cone plug on the breather, and the reducer can start to operate. Appropriate grade of lubricant must be selected, appropriate refueling amount must be controlled, and oil must be changed in time according to the specified requirements, especially the first oil change after 100 hours of use.

- If abnormal situations occur during use, stop the machine and check and deal with it in time. (The highest allowable oil temperature of the reducer is 95 degrees Celsius. Under this temperature limit, as long as the oil temperature does not rise, it can be used with confidence).

Motors for Worm Reducers

Worm reducers and electric motors are closely related in the industrial field. The worm reducer can reduce the speed and increase the output torque, while the electric motor provides power to the reducer. Without a suitable electric motor, the worm reducer cannot function properly. Therefore, it is essential to select the right electric motor for the reducer. At HZPT, we not only provide various types of worm reducers but also offer various electric motors for sale to ensure proper functioning of your system.

معلومات عنا

Ever-power is a comprehensive transmission equipment manufacturer with over 25 years of experience in the design, production, manufacture, and sales of gearboxes. Our products are widely used in various industries, such as the equipment industry, food industry, car washing industry, packaging industry, and automation industry. We are committed to providing our customers with high-quality products, efficient services, and competitive prices. Our gearboxes are designed with high-quality materials and have undergone rigorous testing to ensure their long service life and high efficiency.

At Ever-power, we have a strong research and development team, advanced production equipment, and a comprehensive quality management system to ensure the high quality of our products. Our main customers are located in Europe and the United States, and we have earned their trust and recognition. We encourage our customers to explore our products and contact us for purchasing.

الأسئلة والأجوبة

Q: Can WPWKS Universal Speed Cast Iron Worm Gear Reducer be used in harsh environments?

A: Yes, WPWKS Universal Speed Cast Iron Worm Gear Reducer is suitable for use in harsh environments due to its high-strength cast iron shell.

Q: What is the maximum output torque of WPWKS Universal Speed Cast Iron Worm Gear Reducer?

A: The maximum output torque of WPWKS Universal Speed Cast Iron Worm Gear Reducer can reach 18000Nm.

Q: Does Ever-power provide customized solutions for worm reducer and electric motor matching?

A: Yes, we have a team of professionals who can provide customized solutions for our customers.

Q: What industries are WPWKS Universal Speed Cast Iron Worm Gear Reducers commonly used in?

A: WPWKS Universal Speed Cast Iron Worm Gear Reducers are commonly used in various industries, such as the equipment industry, food industry, car washing industry, packaging industry, and automation industry.

Q: How important is it to select the right electric motor for the worm reducer?

A: It is crucial to select the right electric motor for the worm reducer as the electric motor provides power to the reducer. Without a suitable electric motor, the worm reducer cannot function properly.

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...