In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

WPDKA Single Stage Cast Iron Worm Reducer: A Powerful Solution for Your Power Transmission Needs

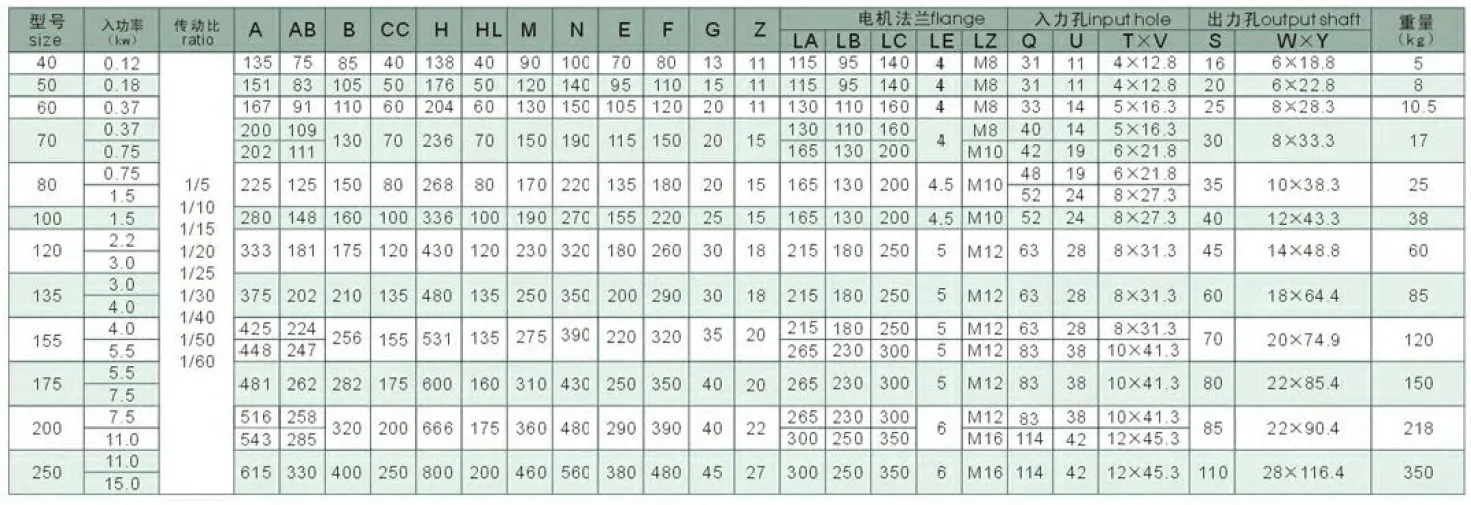

WPDKA Series Worm Gearboxes

A worm gearbox is a power transmission mechanism that uses the speed converter of the gear to reduce the rotation number of the motor (motor) to the required rotation number and obtain ample torque. A worm gearbox is widely used in the transmission of power and motion. The gear of the worm gearbox is generally made of high-strength alloy material with high precision and good contact. The worm gear reducer produced by our company has the advantages of high transmission efficiency, stable operation, small noise control, small volume, lightweight, long service life, and so on.

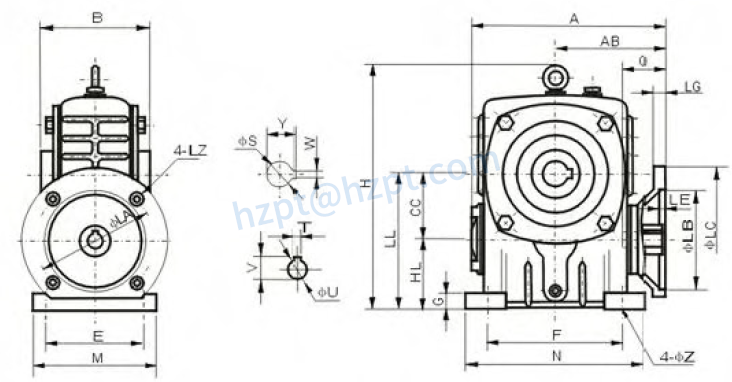

Product Specifications

Features of WPDKA Series Worm Gearboxes:

1. Stable transmission, low vibration, impact, and noise, large reduction ratio, broad versatility, and suitable for use with various mechanical equipment.

2. Large transmission ratio can be obtained by single-stage transmission with a compact structure. Most reducers have suitable self-locking properties and can save the brake device for mechanical equipment requiring brakes.

3. The meshing friction loss between worm screw teeth and worm gear surface is relatively large, so the transmission efficiency is lower than that of the gear, it is easy to be heated, and the temperature is higher.

4. Higher requirements for lubrication and cooling.

5. Good interfitting. National standards manufacture the worm and worm.

What Are the Causes of Excessive Vibration of Worm Gearboxes?

1. Rotor mechanical unbalance

The imbalance mentioned here refers to the imbalance in the static state of the rotor and the imbalance in the rotating state. The rotor deviates from the axis, deflects, and produces abnormal vibration under centrifugal force.

2. Transmission disorder

When the calibration line between the motor and the driver in the worm gear reducer is not good, and it is easy to produce vibration, adjust the calibration line and reinstall the connection between the driver and the motor to stabilize the rotation of the motor bearing.

3. Loose rotor parts

Some parts of the motor rotor: commutator, magnetic pole, belt pulley, etc. Generally, in this case, the rotor will have noise. This looseness will also occur after the reducer has been used for a long time. These situations will be handled as soon as possible because the consequences will become more and more severe after a long time.

4. Large base vibration

In some cases, the excessive vibration of the base also impacts. The vibration frequency of the ground can be said to be the speed of the worm gear reducer. There may be a problem in the design of the base, resulting in an unstable state in operation.

5. Excessive bearing wear

When the bearing works for a long time, the bearing clearance is too large or unbalanced, resulting in bearing friction heating and friction between the rotor and stator, directly damaging the bearing. The sliding bearing is prone to vibration because it has the dense effect of lubricating oil; the machine shaft will float, which can also be related to the bearing weight. If the bearing weight is more significant, the wear will be faster.

Packing and Transportation

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...