In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

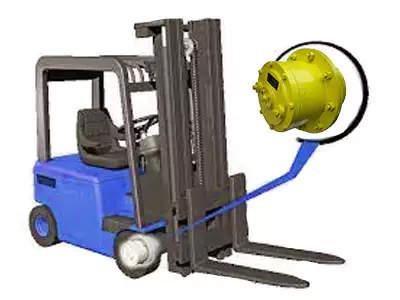

Wheel Drive Planetary Gearbox for Forklift Material Handling Vehicles

The Wheel Drive Planetary Gearbox is designed specifically for forklift material handling vehicles, enhancing their efficiency and performance. This gearbox provides optimal torque and speed control, enabling forklifts to maneuver heavy loads with ease. Its robust design ensures durability and reliability, making it an essential component for improving operational capabilities in warehouses and industrial settings.

Parameter

| Specification | Details |

|---|---|

| Output torque range | 1000-60000 N.m |

| Gear ratios | i=5.3-142 |

| Support | The gearbox has rotating housing flanges to fit wheel |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulically released parking brake |

| Others | EP600L Series wheel drives with manual disconnect application |

| Load capacity | Large radial and axial load capacity due to the use of strong tapered roller bearings |

| Oil seal protection | Reliable oil seal protection, designed according to our field experience |

| Mounting flanges | Universal and SAE input direct mounting flanges |

| Direct mounting | The units are designed for their direct mounting into the wheel rims |

| Interchangeability | Technical data and installation dimension of EP600L Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 600 Series, so these three can be used interchangeably |

| Track drives Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP601 L1A | 1750 | 5.77 | 1000 | 450-600 |

| EP603 L2A | 4000 | 19-23-32-40 | 3000 | 210 |

| EP603 L2B | 4000 | 19-23-32-40 | 3000 | 210 |

| EP602 L2 | 5000 | 12.4-25.8 | 3000 | - |

| EP605 L2 | 7000 | 22-27-30-42-53 | 3000 | 220-310 |

| EP606 L2, L3 | 12000 | 30-35-43-68-79 | 3000 | 300-800 |

| EP607 L2, L3 | 17000 | 33-75-108 | 3000 | 300-600 |

| EP609 L2, L3 | 23000 | 33-142 | 3000 | 300-600 |

| EP610 L2, L3 | 30000 | 20-111 | 3000 | 300-800 |

| EP611 L2, L3 | 36000 | 41-47 | 3000 | 300-800 |

| EP613 L3 | 45000 | 108 | 3000 | 300-800 |

| EP615 L3 | 60000 | 108 | 3000 | 300-1000 |

Characteristics and Benefits of Wheel Drive Planetary Gearbox for Forklift Material Handling Vehicles

The Wheel Drive Planetary Gearbox for Forklift Material Handling Vehicles is designed to enhance the performance and efficiency of forklifts. Below are its key characteristics and benefits:

- High Torque Capacity: This gearbox can handle high torque loads, making it suitable for heavy-duty applications in material handling.

- Compact Design: The compact structure allows for easy installation in limited spaces, ensuring versatility in different forklift models.

- Durability: Constructed with high-quality materials, the gearbox is built to withstand harsh working environments, providing long-lasting reliability.

- Efficiency: The planetary gear design minimizes energy loss, resulting in improved fuel efficiency and lower operational costs.

- Smooth Operation: Designed for quiet operation, it reduces noise levels during the lifting and lowering of loads, contributing to a better working environment.

- Low Maintenance: The gearbox requires minimal maintenance, allowing for more uptime and less disruption in operations.

- Versatile Applications: Ideal for various material handling tasks, it enhances the functionality of forklifts in warehouses, construction sites, and distribution centers.

How to Choose a Wheel Drive Planetary Gearbox for Forklift Material Handling Vehicles

When selecting a Wheel Drive Planetary Gearbox, consider the following factors:

- Load Type: Assess the maximum load the gearbox will handle. Different loads may require different gear ratios and materials for optimal performance.

- Working Environment: Evaluate the environment where the gearbox will operate. Factors such as temperature, humidity, and exposure to dust or chemicals can impact the gearbox's durability and efficiency.

- Installation Method: Choose between flange connection and shaft output based on the installation requirements of your forklift. Ensure compatibility with existing components to facilitate easier integration and maintenance.

Maintenance of Wheel Drive Planetary Gearbox for Forklift Material Handling Vehicles

Proper maintenance of the wheel drive planetary gearbox is essential for optimal performance and longevity. Follow these guidelines:

- Regular Inspection: Frequently check for leaks, unusual noises, and signs of wear.

- تشحيم: Ensure that the gearbox is properly lubricated with the recommended oil to prevent overheating and friction.

- Temperature Monitoring: Keep an eye on the operating temperature; excessive heat can indicate issues.

- Filter Replacement: Replace oil filters as needed to maintain fluid cleanliness.

- Professional Servicing: Schedule periodic professional assessments to catch potential problems early.

Wheel Drive Planetary Gearbox Manufacturer

RP Techniek is the sales agent for Ever-power Group in Australia and the Netherlands, ranking among the top ten suppliers in the Netherlands. We specialize in Wheel Drive Planetary Gearboxes for forklift material handling vehicles, offering a range of products and services to meet diverse customer needs.

Our customization services ensure that we design gear ratios and installation methods according to specific client requirements. We pride ourselves on high-quality manufacturing, utilizing precision machining to guarantee low tolerances and extended lifespan of our products. Furthermore, we provide technical support, including selection guidance and after-sales services.

Our gearboxes help reduce the complexity of the drive system while enhancing the overall performance and reliability of your equipment. We encourage customers to reach out for customized solutions that can elevate their operations and efficiency.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...