In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

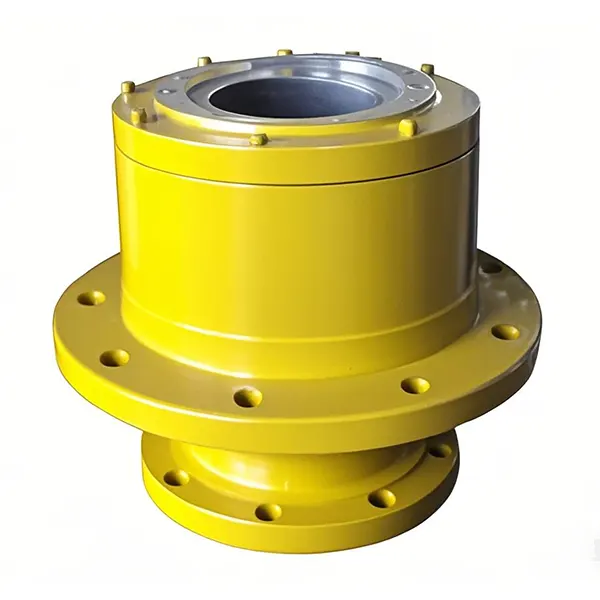

Wheel Drive for Feed Mixer

The Wheel Drive for Feed Mixer is an essential component designed to enhance the efficiency of feed mixing operations. This drive system provides reliable power and smooth movement, ensuring thorough mixing of feed components. By optimizing the mixing process, it helps improve the consistency and quality of animal feed, ultimately supporting better livestock health and productivity.

Parameters for Wheel Drive for Feed Mixer

| Specification | Details |

|---|---|

| Output torque range | 1000-60000 N.m |

| Gear ratios | i=5.3-142 |

| Support | The gearbox has rotating housing flanges to fit wheel |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulically released parking brake |

| Others | EP600L Series wheel drives with manual disconnect application |

| Load capacity | Large radial and axial load capacity due to the use of strong tapered roller bearings |

| Oil seal protection | Reliable oil seal protection, designed according to our field experience |

| Mounting flanges | Universal and SAE input direct mounting flanges |

| Direct mounting | The units are designed for their direct mounting into the wheel rims |

| Interchangeability | Technical data and installation dimension of EP600L Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 600 Series, so these three can be used interchangeably |

| Track drives Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP601 L1A | 1750 | 5.77 | 1000 | 450-600 |

| EP603 L2A | 4000 | 19-23-32-40 | 3000 | 210 |

| EP603 L2B | 4000 | 19-23-32-40 | 3000 | 210 |

| EP602 L2 | 5000 | 12.4-25.8 | 3000 | - |

| EP605 L2 | 7000 | 22-27-30-42-53 | 3000 | 220-310 |

| EP606 L2, L3 | 12000 | 30-35-43-68-79 | 3000 | 300-800 |

| EP607 L2, L3 | 17000 | 33-75-108 | 3000 | 300-600 |

| EP609 L2, L3 | 23000 | 33-142 | 3000 | 300-600 |

| EP610 L2, L3 | 30000 | 20-111 | 3000 | 300-800 |

| EP611 L2, L3 | 36000 | 41-47 | 3000 | 300-800 |

| EP613 L3 | 45000 | 108 | 3000 | 300-800 |

| EP615 L3 | 60000 | 108 | 3000 | 300-1000 |

Characteristics and Benefits of Wheel Drive for Feed Mixer

The Wheel Drive for Feed Mixer is designed to enhance the efficiency and performance of feed mixing processes. This innovative system offers several key characteristics and benefits:

- Durability: Constructed with high-quality materials, the wheel drive ensures longevity and withstands heavy usage in demanding environments.

- Efficient Power Transmission: The wheel drive mechanism provides optimal power transfer, reducing energy consumption and improving overall operational efficiency.

- Easy Maintenance: The design allows for straightforward maintenance procedures, minimizing downtime and lowering operational costs.

- Enhanced Mixing Quality: The precise control of mixing speeds and patterns results in a uniform blend of feed, which is crucial for livestock nutrition.

- Versatility: Suitable for various types of feed and mixing applications, the wheel drive can be adapted to meet specific operational needs.

- Improved Safety: Incorporating safety features, this system minimizes risks associated with feed mixing processes, ensuring a safer working environment.

In summary, the Wheel Drive for Feed Mixer combines durable construction, efficient performance, and user-friendly features, making it an essential tool for modern feed mixing operations.

How to Choose a Wheel Drive for Feed Mixer

When selecting a Wheel Drive for a Feed Mixer, consider the following factors:

- Load Type: Assess the weight and density of the feed materials to ensure the drive can handle the required torque and power.

- Working Environment: Evaluate the conditions where the mixer will operate, including temperature, humidity, and exposure to dust or chemicals, to choose a durable and appropriate drive.

- Installation Method: Decide between flange connection or shaft output based on the mixer design and space constraints to ensure a secure and efficient installation.

Maintenance of Wheel Drive for Feed Mixer

To ensure optimal performance of the Wheel Drive for Feed Mixer, regular maintenance of the planetary gearbox is crucial. Follow these guidelines:

- Check Lubrication: Regularly inspect the oil level and quality; replace oil as necessary to prevent wear.

- Inspect Seals and Gaskets: Examine seals for leaks; replace any damaged components to maintain integrity.

- Monitor Temperature: Keep an eye on operating temperatures; excessive heat can indicate potential issues.

- Tighten Fasteners: Periodically check and tighten all bolts and fasteners to ensure stability.

- Conduct Vibration Analysis: Regularly assess vibrations to identify misalignment or wear in gears.

Wheel Drive Planetary Gearbox Manufacturer

RP Techniek is the sales agent for Ever-power Group in Australia and the Netherlands, recognized as one of the top ten suppliers in the Netherlands.

Our Wheel Drive solutions for feed mixers are tailored to meet the diverse needs of our clients. We offer customized services, designing gear ratios and installation methods based on individual requirements. Our high-quality manufacturing processes involve precision machining, ensuring low tolerances and a long lifespan for our products. Technical support is also a key aspect of our service, providing selection guidance and after-sales assistance to our customers.

By simplifying the complexity of drive systems, we enhance the overall performance and reliability of your equipment. We encourage all clients to consider our customized solutions and make a purchase to experience the benefits of our advanced gearbox technology.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...