In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

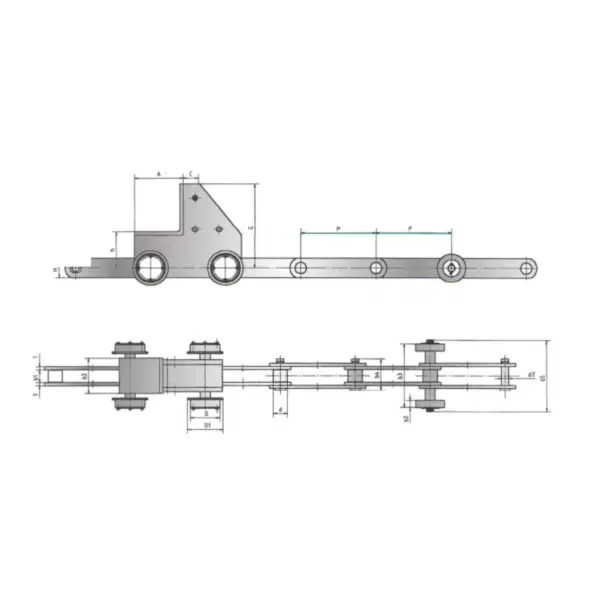

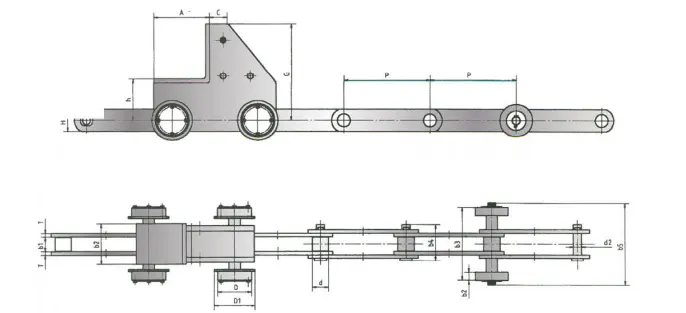

Details of Stainless Steel Metallurgical Lifting Chain

| Pitch | Width Between Inner Plates |

Roller Diameter |

Pin Diameter |

Plate سماكة |

Attachment Dimension | Ultimate Tensile Strength |

||||||||||

| b1 | d1 | d2 | b4 | b5 | ح | T | h | A | ج | G | b2 | د | د1 | b3 | KN | |

| 315 | 55 | 60 | 30 | 133 | 310 | 82 | 13 | 170 | 205 | 70 | 360 | 180 | 125 | 149 | 274 | 450 |

مقدمة

Stainless steel metallurgical lifting chains are high-quality chains used for heavy-duty lifting operations in various industries. These chains are made of top-grade stainless steel material, which makes them sturdy, corrosion-resistant, and long-lasting. The following article will provide a comprehensive guide to this product, its features, and applications.

Construction and Material

Every stainless steel metallurgical lifting chain consists of several components, including links, pins, and rollers. These components are made of high-quality stainless steel material that offers excellent strength, corrosion resistance, and durability. The chains undergo rigorous testing to ensure that they meet the required standards for load capacity and strength.

Features

The stainless steel metallurgical lifting chain offers several outstanding features that make it an ideal choice for heavy-duty lifting operations. These features include high strength, excellent corrosion resistance, durability, and wear resistance. The chains are also resistant to high temperatures and exposure to chemicals, making them ideal for use in harsh environments.

التطبيقات

The stainless steel metallurgical lifting chain is used in various industries, including construction, mining, oil and gas, marine, and manufacturing. They are used for heavy-duty lifting operations such as moving heavy machinery, lifting goods on ships, and hoisting materials in mines and construction sites.

صيانة

To ensure that the stainless steel metallurgical lifting chain lasts for a long time, proper maintenance is critical. The chain should be inspected regularly for wear and tear, and any damaged links or parts should be replaced immediately. The chain should also be lubricated regularly to prevent rust and corrosion.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. We take pride in offering high-quality Stainless Steel Metallurgical Lifting Chains that are designed to meet the specific needs of the industry.

Our chains are manufactured using top-grade stainless steel, ensuring exceptional strength and durability. With a focus on precision engineering, our chains deliver reliable performance even in the harshest environments.

At RP Techniek BV, we understand the importance of providing excellent service to our customers. Our knowledgeable team is dedicated to assisting you in finding the perfect chain solution for your metallurgy industry requirements.

In addition to the Stainless Steel Metallurgical Lifting Chains, we also offer a wide range of other stainless steel roller chains. We have a diverse selection to suit various industrial applications, ensuring that you can find the right chain for your specific needs.

With our extensive production capabilities, we can fulfill your chain requirements efficiently and with uncompromising quality.

How to Select Suitable Sprockets?

When it comes to selecting the right sprockets for your Stainless Steel Metallurgical Lifting Chain, there are a few key factors to consider. Firstly, you need to ensure that the sprocket matches the pitch of your lifting chain. The pitch refers to the distance between consecutive chain links, and it is crucial to choose a sprocket with the same pitch to ensure proper engagement.

Another important consideration is the number of teeth on the sprocket. The number of teeth determines the speed ratio between the driving and driven sprockets. It is essential to select a sprocket with the appropriate number of teeth to achieve the desired speed and torque output.

Furthermore, the material of the sprocket plays a significant role in its performance and durability. Stainless steel sprockets are an excellent choice for applications that require corrosion resistance and high strength. They are ideal for environments exposed to moisture, chemicals, or extreme temperatures.

At our company, we offer a wide range of sprockets to cater to different needs and applications. Whether you require standard sprockets, custom-made sprockets, or sprockets with special coatings, we have you covered. Our sprockets are meticulously designed and manufactured to ensure excellent performance, reliability, and longevity.

معلومات إضافية

| Edited by | Zqq. |

|---|

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...