In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

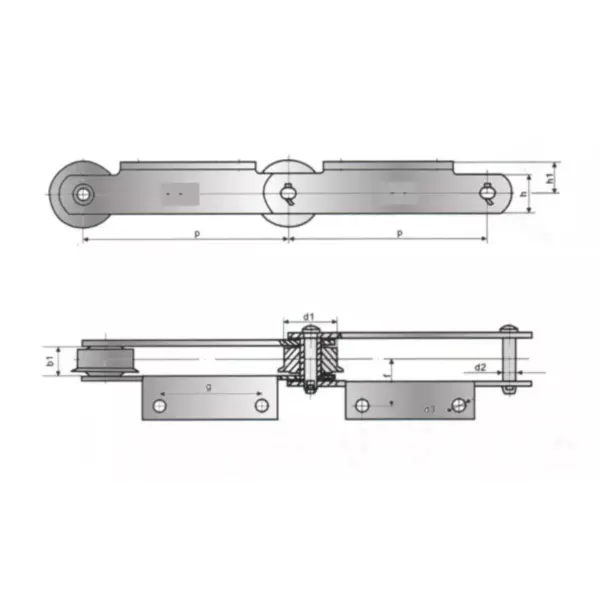

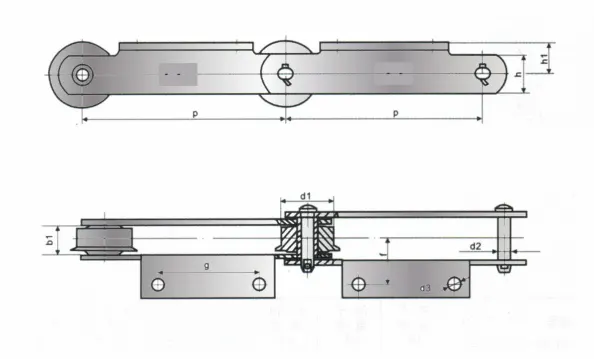

Details of Stainless Steel Metallurgical Conveyor Machine Chain

| Pitch | Width Between Inner Plates |

Roller Diameter |

Pin Diameter |

Plate Height |

Bending Height |

Attachment Dimension | Weight Per Meter |

Ultimate Tensile Strength |

Note | ||

| ص | b1 | d1 | d2 | h | h1 | f | g | d3 | Q | ||

| مم | مم | مم | مم | مم | مم | مم | مم | مم | kg/m | KN | Note |

| 150 | 36 | 70/85 | 18 | 51 | 51 | 61 | 40 | 9 | 17.9 | 160 | BTL800 |

| 150 | 45.5 | 67/75 | 15 | 41 | 40 | 50 | 55 | 12 | 11.3 | 160 | 1000T/H |

| 250 | 51.4 | 80/110 | 19.5 | 50.8 | 45 | 75 | 125 | 15 | 23.2 | 250 | 2111 |

| 250 | 37.1 | 65/80 | 15.88 | 44.5 | 38 | 60 | 125 | 15 | 14.3 | 190 | 2139 |

| 250 | 62 | 100/125 | 28 | 65 | 60 | 111 | Single Hole | 22 | 33.9 | 240 | 21.01 |

| 300 | 108 | 136/160 | 50 | 120 | 100 | 150 | 140 | 27 | 87 | 720 | 1.03 |

| 300 | 77 | 125/150 | 36 | 80 | 70 | 131 | Single Hole | 27 | 53.9 | 370 | 4.02,14.03 |

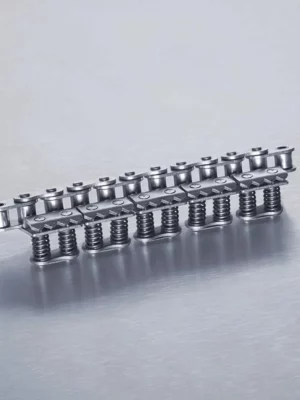

What is a Stainless Steel Metallurgical Conveyor Machine Chain?

A Stainless Steel Metallurgical Conveyor Machine Chain is a type of chain used in metallurgical conveyor machines. It is made from high-quality stainless steel, which provides excellent corrosion resistance and makes it ideal for use in harsh environments.

Types of Stainless Steel Metallurgical Conveyor Machine Chains

There are several types of Stainless Steel Metallurgical Conveyor Machine Chains available in the market. Some of the most common types include:

- Standard Stainless Steel Metallurgical Conveyor Machine Chain

- Double Pitch Stainless Steel Metallurgical Conveyor Machine Chain

- Hollow Pin Stainless Steel Metallurgical Conveyor Machine Chain

- Side Bow Stainless Steel Metallurgical Conveyor Machine Chain

Features of Stainless Steel Metallurgical Conveyor Machine Chains

Stainless Steel Metallurgical Conveyor Machine Chains come with a range of features that make them suitable for use in various applications. Some of these features include:

- High corrosion resistance

- High tensile strength

- Low maintenance

- Resistance to wear and tear

- Ability to withstand high temperatures

- عمر خدمة طويل

Applications of Stainless Steel Metallurgical Conveyor Machine Chains

Stainless Steel Metallurgical Conveyor Machine Chains are used in various applications in the metallurgical industry. Some of the most common applications include:

- Conveying raw materials and finished products

- Conveying hot and cold materials

- Conveying abrasive materials

- Conveying materials in harsh environments

- Conveying materials in high-temperature environments

Advantages of Stainless Steel Metallurgical Conveyor Machine Chains

Stainless Steel Metallurgical Conveyor Machine Chains offer a range of advantages over other types of chains. Some of the most significant advantages include:

- عمر خدمة طويل

- High resistance to corrosion

- High resistance to wear and tear

- متطلبات صيانة منخفضة

- Ability to operate in harsh environments

- Ability to operate in high-temperature environments

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV is the Netherlands sales agent of Ever-power Group. Our Stainless Steel Metallurgical Conveyor Machine Chain is a product that is unique to our company. Our product is made with high-quality materials and is built to last, ensuring that your production line will run smoothly and efficiently.

Our company prides itself on providing excellent customer service and support. We are always available to answer any questions you may have and to provide you with the information you need to make an informed decision. Our goal is to help you find the perfect chain for your needs and to ensure that you are completely satisfied with your purchase.

In addition to our Stainless Steel Metallurgical Conveyor Machine Chain, we also offer a wide range of other stainless steel roller chains for sale. Our products are designed to meet the needs of a variety of industries, from food processing to industrial manufacturing.

At RP Techniek BV, we are committed to providing our customers with the highest quality products and services. We have the production capabilities to handle orders of any size and we are always looking for ways to improve our products and processes.

Please see the attached image for a visual representation of our products. For more information or to place an order, please contact us today.

How to Select Suitable Sprockets?

If you are using a Stainless Steel Metallurgical Conveyor Machine Chain, it is essential to select the appropriate sprockets to ensure the smooth functioning of the machinery.

The first step is to determine the pitch of the chain, which refers to the distance between any three consecutive pins on the chain. Once you have established the pitch, you can select a sprocket with the same pitch.

Other factors to consider when selecting sprockets include the number of teeth on the sprocket and the bore size. The number of teeth on the sprocket should be such that it allows the chain to move smoothly without any slipping. The bore size should match the shaft size on which the sprocket is mounted.

At our company, we offer a wide range of sprockets, including those made from different materials such as stainless steel and aluminum. We also provide sprockets with varying numbers of teeth and bore sizes to suit different requirements.

معلومات إضافية

| Edited by | Zqq. |

|---|

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...