In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications

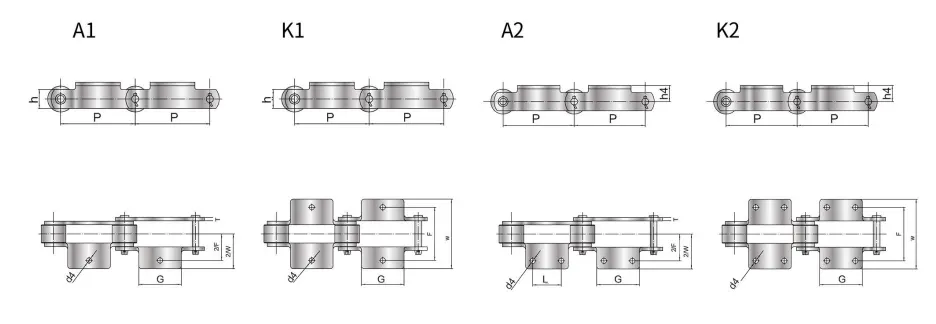

RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF08150 has the following parameters:

| Chain No. | Roller Type | Pitch (P) |

h4 | 2/F | ف | 2W | W | ل | T | d4 | Bolt Dimension |

Weight of SA2 att.(KG) |

|

| RF0375 | R/F/S | 75 | 20 | 30 | 60 | 46 | 92 | 30 | 55 | 3.2 | 10 | M8 | 0.05 |

| RF03100 | R/F/S | 100 | 20 | 30 | 60 | 46 | 92 | 40 | 65 | 3.2 | 10 | M8 | 0.06 |

| RF430 | R/S | 101.6 | 22 | 40 | 80 | 54 | 108 | 40 | 70 | 4.8(5.0) | 12 | M10 | 0.11 |

| RF05075 | س | 75 | 22 | 35 | 70 | 47 | 94 | 30 | 55 | 4.5 | 10 | M8 | 0.07 |

| RF05100 | R/F/S | 100 | 22 | 35 | 70 | 47 | 94 | 40 | 65 | 4.5 | 10 | M8 | 0.08 |

| RF05150 | R/F/S | 150 | 22 | 35 | 70 | 47 | 94 | 60 | 85 | 4.5 | 10 | M8 | 0.1 |

| RF204 | س | 66.27 | 24 | 45 | 90 | 59 | 118 | - | 35 | 6.3(6.0) | 12 | M10 | 0.08 |

| RF450 | R/F/S/M | 101.6 | 28 | 50 | 100 | 64 | 128 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.18 |

| RF08150 | R/F/S/M | 150 | 28 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF650 | R/F/S/M | 152.4 | 32 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF10100 | R/S/M | 100 | 28 | 50 | 100 | 65 | 130 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.16 |

| RF10150 | R/F/S/M | 150 | 28 | 50 | 100 | 65 | 130 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.2 |

| RF214 | R/S/M | 101.6 | 35 | 55 | 110 | 73 | 146 | 40 | 80 | 7.9 | 15 | M12 | 0.28 |

| RF205 | س | 78.11 | 35 | 60 | 120 | 75 | 150 | 30 | 65 | 7.9 | 12 | M10 | 0.23 |

| RF6205 | R/F/S/M | 152.4 | 38 | 60 | 120 | 79 | 158 | 60 | 100 | 7.9 | 15 | M12 | 0.37 |

| RF12200 | R/F/S/M | 200 | 38 | 60 | 120 | 79 | 158 | 80 | 120 | 7.9 | 15 | M12 | 0.45 |

| RF12250 | R/F/S/M | 250 | 38 | 60 | 120 | 79 | 158 | 125 | 170 | 7.9 | 15 | M12 | 0.62 |

| RF212 | R/S/M | 152.4 | 45 | 65 | 130 | 83 | 166 | 60 | 100 | 9.5(10.0) | 15 | M12 | 0.49 |

| RF17200 | R/F/S/M | 200 | 45 | 75 | 150 | 98 | 196 | 80 | 120 | 9.5(10.0) | 15 | M12 | 0.66 |

| RF17250 | R/F/S/M | 250 | 45 | 75 | 150 | 98 | 125 | 125 | 170 | 9.5(10.0) | 15 | M12 | 0.86 |

Title 1: Overview of RF Type Conveyor Chain

The RF Type Conveyor Chain is a highly durable and efficient chain that is specifically designed for conveying heavy loads in various industries. It offers excellent strength and reliability, making it ideal for applications that require a high level of performance and longevity.

Title 2: A1 Attachment for Enhanced Functionality

The A1 attachment on the RF Type Conveyor Chain provides enhanced functionality, allowing for attachments or accessories to be added to the chain. This enables the chain to perform additional tasks or carry specific types of loads, increasing its versatility and adaptability in different operating environments.

Title 3: K1 Attachment for Precise Positioning

The K1 attachment is a specialized feature of the RF Type Conveyor Chain that allows for precise positioning of the conveyed items. It ensures accurate alignment and control, making it suitable for applications that require precise movement or positioning of the loads, such as assembly lines or automated systems.

Title 4: A2 Attachment for Increased Load Capacity

The A2 attachment is specifically designed to increase the load capacity of the RF Type Conveyor Chain. By incorporating the A2 attachment, the chain's overall strength and load-bearing capacity are significantly enhanced, enabling it to handle heavier loads without compromising performance or durability.

Title 5: K2 Attachment for Improved Stability

The K2 attachment plays a crucial role in improving the stability of the RF Type Conveyor Chain during operation. It provides additional support and prevents excessive movement or vibration, ensuring smooth and stable conveying of the loads. The K2 attachment is particularly beneficial in applications where stability is vital, such as heavy-duty material handling or transportation systems.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. We take pride in offering our customers the highest quality products with exceptional customer service. Our stainless steel roller chains are manufactured to meet the industry's highest standards, providing reliable and consistent performance for our customers.

One of our popular products is the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF08150. This unique chain is designed to withstand heavy loads and extreme conditions, making it an ideal solution for tough applications. It features a simple yet effective attachment design, ensuring a secure and stable connection to the conveyor system.

At RP Techniek BV, we are committed to providing our customers with the best possible products and services. We have a team of experienced professionals who are dedicated to ensuring that our customers receive the support they need. With our state-of-the-art manufacturing facilities, we can produce high-quality stainless steel roller chains that meet even the most demanding specifications.

In addition to the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF08150, we also offer a wide range of other types of stainless steel roller chains. Our products are suitable for various applications, including food processing, packaging, and general manufacturing.

We are confident that our products and services will meet and exceed your expectations. Contact us today to learn more about our stainless steel roller chains and how we can help you with your specific needs.

Sprockets for Sale

When it comes to finding the right sprockets for your RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF08150, our company has got you covered. We offer various types of sprockets that are suitable for your conveyor system.

Our sprockets are made of high-quality materials, ensuring durability and longevity. We have a wide range of sizes available to ensure that you find the perfect fit for your conveyor system. Our sprockets are designed to provide smooth and efficient operation, ensuring that your production line runs smoothly and without interruption.

At our company, we understand that every customer has unique needs. Therefore, we offer custom sprocket options to meet your specific requirements. Our team of experts will work with you to develop the perfect sprocket solution for your unique application.

With our extensive inventory of sprockets, we can guarantee a quick turnaround time for your order. Our competitive pricing and exceptional customer service make us the top choice for all your sprocket needs.

معلومات إضافية

| Editor | Zqq |

|---|

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...