In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

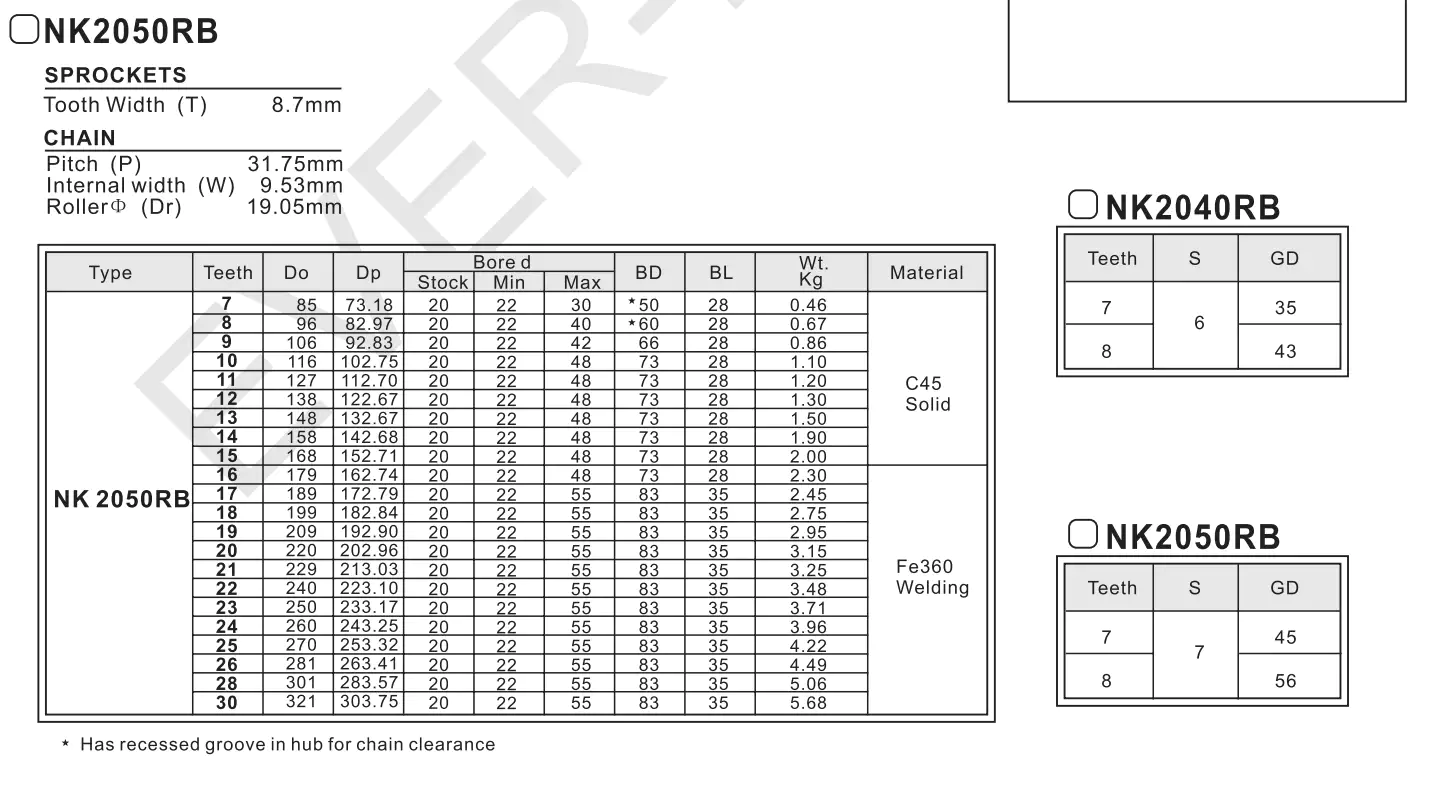

NK2050RB Double Pitch Sprocket

The NK2050RB Double Pitch Sprocket is designed for enhanced performance in power transmission systems. Its robust construction ensures durability, while the double pitch design allows for smoother operation and greater efficiency. Ideal for various industrial applications, it guarantees reliable functionality.

Specifications of NK2050RB Double Pitch Sprocket

The NK2050RB Double Pitch Sprocket is specifically designed for use in power transmission systems and is optimized for compatibility with double pitch chains. This type of sprocket offers several benefits when compared to standard sprockets, such as increased spacing between teeth, improved load capacity, and more efficient operation, making it a valuable component in various machinery.

Definition and Basic Structure

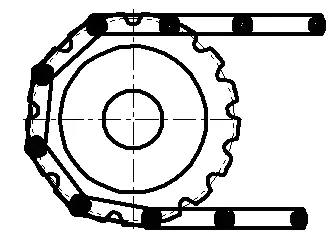

- Definition: A double pitch sprocket is characterized by its larger tooth spacing, which is specifically designed to work with a double pitch chain that has a pitch that is double that of a standard chain.

- Basic structure: This type of sprocket is composed of several components, including a hub, spokes, and teeth, with the teeth being spaced farther apart to accommodate the larger rollers found in double pitch chains.

Main Features

- Larger tooth spacing: The increased distance between teeth allows for the use of a wider chain, thereby facilitating greater power transmission efficiency.

- Higher load capacity: The design of double pitch chains with larger rollers supports a greater load capacity compared to standard chains, making them suitable for heavier applications.

- Smooth operation: The larger tooth profile and spacing of double pitch sprockets contribute to smoother operation and reduced noise during use, enhancing overall performance.

Materials

Double pitch sprockets can be constructed from a range of materials, including carbon steel, alloy steel, and stainless steel, with the material selected based on the specific demands of the application.

- Carbon steel: This is a common choice for applications with lower load requirements and budget considerations.

- Alloy steel: Known for its enhanced strength and longevity, alloy steel is ideal for high-load applications.

- Stainless steel: This material provides excellent resistance to corrosion, making it suitable for use in harsh environments.

Manufacturing Process

The production of our double pitch sprockets involves a methodical manufacturing process with several critical steps:

- Raw material preparation: Selecting and preparing the appropriate grade of steel for either forging or casting.

- Forging or casting: The initial sprocket blank is formed through forging or casting techniques.

- Machining: The blank is then machined to achieve the required dimensions and precise tooth profile.

- Tooth rolling: A specialized rolling machine is used to form the teeth accurately.

- Heat treatment: The sprocket undergoes heat treatment to significantly improve its strength and durability.

- Surface treatment: A protective coating or plating is applied to prevent corrosion.

- Quality inspection: The final sprocket is rigorously inspected to ensure it meets stringent quality standards.

Customization Services

We offer a variety of customization options to ensure you receive the exact double pitch sprocket tailored to your needs:

- Material selection: We provide guidance in selecting the best material for your specific operational requirements.

- Tooth profile design: We offer custom design services for the tooth profile to match your precise specifications.

- Bore and keyway: We customize the bore and keyway to ensure a perfect fit for your shaft.

Sprockets Supplier in the Netherlands

RP Techniek BV acts as the sales agent for Ever-power Group in the Netherlands, supplying high-quality sprockets and related products to meet diverse industrial applications. Among our featured offerings is the NK2050RB Double Pitch Sprocket, engineered for superior durability and efficiency in power transmission systems. Our sprockets are produced using cutting-edge techniques and materials, ensuring high reliability and performance even in demanding conditions.

In addition to our standard sprockets, we also provide customized solutions that cater to the unique specifications of our clients. We invite customers to bring their designs and samples for bespoke manufacturing. Your specific requirements are our utmost priority, and we are committed to delivering outstanding products and services that support your operational needs.

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...