The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Long Worm Gear

The Long Worm Gear is a precision-engineered component designed for effective torque transmission in machinery. Made from high-quality steel, it ensures durability and reliability under heavy loads. The Long Worm Gear plays a crucial role in reducing speed and increasing torque, making it essential for various mechanical applications.

Details of Long Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 10:1 |

| Material | Alloy Steel |

| Output Torque | 500 Nm |

| Input Speed | 1500 RPM |

| Efficiency | 85% |

| Weight | 12 kg |

Features of Long Worm Gear

- High Torque Transmission: The Long Worm Gear design enables efficient torque transfer, making it ideal for applications requiring significant power without increasing the motor size.

- Compact Design: Its compact structure allows for space-saving installations, perfect for machinery with limited space while maintaining high performance.

- Durability: Made from high-quality materials, the Long Worm Gear is designed to withstand wear and tear, ensuring a long operational life even in demanding conditions.

- Low Noise Operation: The unique configuration of the Long Worm Gear minimizes noise during operation, making it suitable for environments where quiet performance is essential.

Applications of Long Worm Gear in Industrial Machinery

The Long Worm Gear is an essential component in various industrial machinery applications, providing efficient power transmission and torque multiplication. Its unique design allows for smooth operation and high load capacity, making it ideal for use in gearboxes, conveyors, and factory automation systems. The Long Worm Gear is particularly beneficial in situations where space is limited, as it can be mounted in compact configurations. By integrating the Long Worm Gear into your machinery, you can enhance performance, increase reliability, and reduce maintenance costs. This versatility makes it a vital choice for engineers and manufacturers alike.

Manufacturing Process of Long Worm Gear

- Material Selection: The first step in the manufacturing process of Long Worm Gear involves selecting high-quality materials that provide durability and strength. Typically, materials like alloy steel or brass are chosen for their excellent wear resistance and ability to withstand high torque. The right material ensures that the Long Worm Gear functions efficiently under varying loads and reduces the risk of damage or failure during operation.

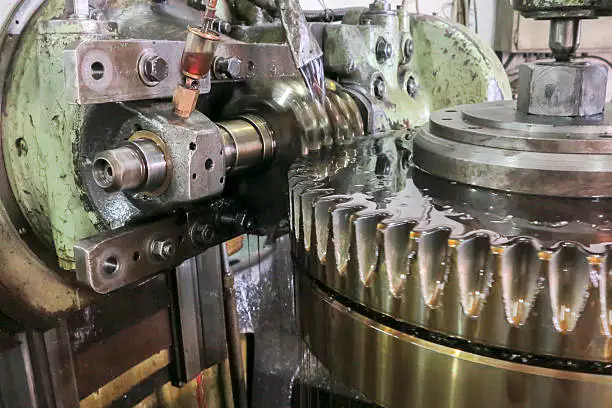

- CNC Machining: After material selection, the next phase in creating Long Worm Gear is CNC machining. This process involves using computer-controlled machines to precisely cut and shape the gear components. CNC machining ensures high accuracy and repeatability, crucial for the intricate designs of worm gears. The machining process allows for the creation of fine threads and grooves that are essential for the optimal performance of the Long Worm Gear.

- Heat Treatment: The heat treatment process follows machining and is vital for enhancing the mechanical properties of the Long Worm Gear. This process involves heating the gear to a specific temperature and then cooling it rapidly. Heat treatment improves hardness and strength, reducing the likelihood of wear during operation. This stage is critical in ensuring that the Long Worm Gear can handle demanding applications and maintain longevity.

- ضبط الجودة: Quality control is an integral part of the manufacturing process for Long Worm Gear. Each component undergoes rigorous testing to ensure it meets industry standards. This includes checking for dimensional accuracy, surface finish, and material properties. Quality control helps identify any defects early in the process, ensuring that only the highest quality Long Worm Gears are delivered to customers.

- Assembly and Final Inspection: The final steps in the manufacture of Long Worm Gear include assembly and a comprehensive inspection. The components are carefully assembled, and the gear is tested under operational conditions. This ensures that the Long Worm Gear performs as intended in real-world applications. Final inspection verifies that all specifications are met, ensuring product reliability and customer satisfaction.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group, and we are proud to be one of the top ten worm gear suppliers in the Netherlands.

Our product offerings include:

- High-Quality Manufacturing: We ensure that all our worm gears are produced with the highest standards, utilizing advanced technology and materials.

- Exceptional Durability: Our worm gears are designed to withstand rigorous conditions, providing reliable performance over time.

- Strong Industry Expertise: With years of experience in the industry, we bring unparalleled knowledge and skills to meet our clients' needs.

- Outstanding Customer Service: We prioritize customer satisfaction, offering tailored solutions and prompt support to all our clients.

For a visual representation of our products, please see the image below:

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...