In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

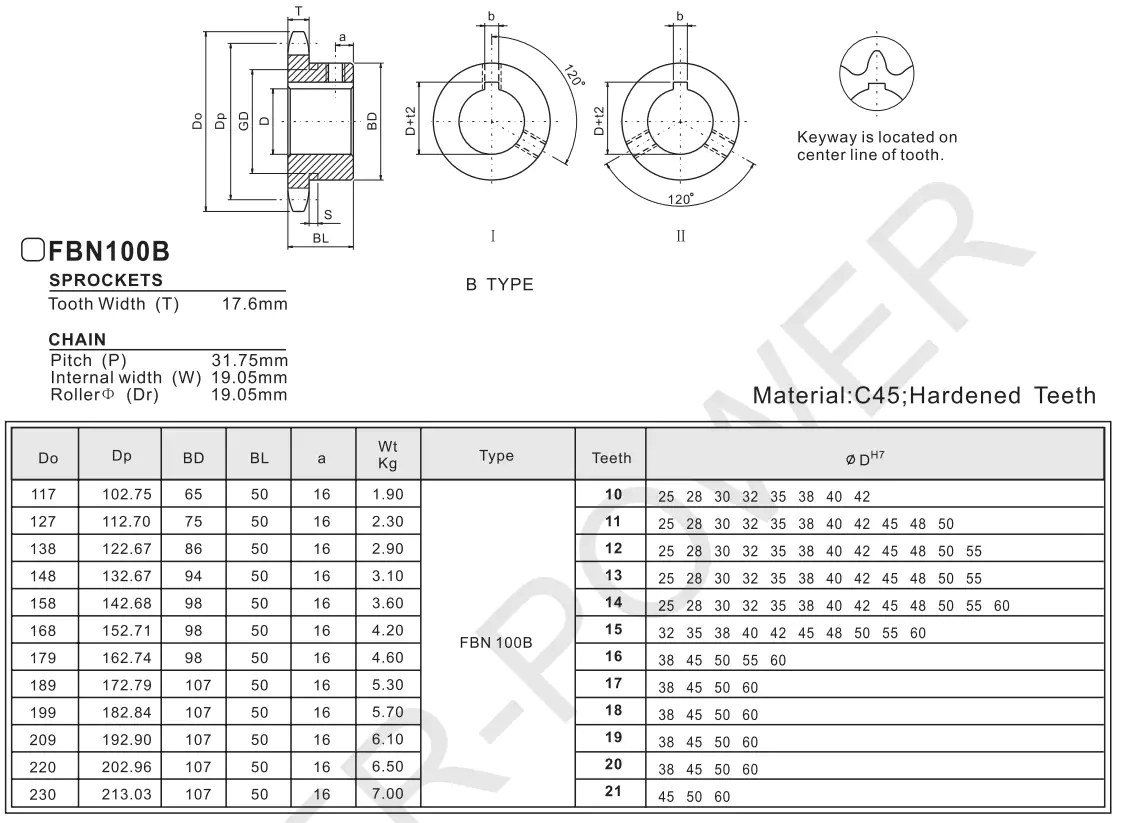

FBN100B Finished Bore Sprocket

The FBN100B Finished Bore Sprocket is designed for precision and durability in various industrial applications. Constructed from high-quality materials, it ensures efficient power transmission and enhanced performance. With its finished bore feature, installation is straightforward, making it an ideal choice for machinery requiring reliable and robust drive components.

Specifications of FBN100B Asian Standard Finished Bore Sprocket

Introduction to Finished Bore Sprocket

A finished bore sprocket is designed with a pre-machined hole, allowing it to fit onto a specific shaft size precisely. Among various types of sprockets used in numerous industries, the FBN100B Asian Standard finished bore sprocket stands out as one of the most common. Its reputation is built upon its accuracy, robust construction, and ease of installation, making it a preferred choice in mechanical systems.

Materials and Manufacturing Process

The FBN100B Asian Standard finished bore sprocket is manufactured with high-quality materials, including high-carbon steel, alloy steel, or stainless steel. The choice of material depends on the application and operational conditions it will face. The process involves multiple stages: material selection, cutting, stamping, forging, machining, heat treatment, surface hardening, rust prevention, and thorough quality testing.

- Material Selection: Choosing the right materials is crucial, influenced by the specific application and operating conditions. High-carbon steel is used where high strength and durability are essential. Alloy steel provides enhanced wear and corrosion resistance, while stainless steel is ideal for applications where rust prevention and hygiene are critical.

- Cutting: In this step, the raw material is shaped and sized using various cutting instruments such as saws, laser cutters, or water jets, ensuring precision in design.

- Stamping: The stamping process shapes the material by pressing or punching it into a specific form using a die, allowing for consistent and accurate designs.

- Forging: Forging is a method where pressure is applied through a hammer or press to shape the material, enhancing its strength and structural integrity.

- Machining: This stage involves cutting the material down to its final dimensions and specific shape with equipment like lathes, milling machines, or drills, further ensuring precise tolerances.

- Heat Treatment: Heat treatment involves heating and subsequently cooling the sprocket material to improve its mechanical characteristics. The FBN100B sprocket undergoes both quenching and tempering, which are essential for achieving an optimal balance of hardness and toughness.

- Surface Hardening: This process enhances wear resistance by hardening the exterior surface of the sprocket, typically achieved through techniques such as induction hardening.

- Rust Prevention: To extend the service life of the sprocket, a rust prevention treatment is applied, which is vital to protect it from corrosion and ensure longevity.

- Quality Testing: Rigorous quality testing is essential to confirm that the finished product meets the required specifications. This testing includes dimensional inspections, hardness assessments, and surface evaluations prior to shipping to customers.

Applications of FBN100B Finished Bore Sprocket

The FBN100B finished bore sprocket finds extensive applications in various sectors such as heavy machinery, food processing, chemical and pharmaceutical industries, assembly lines, and logistics.

- Heavy Machinery and Equipment: These sprockets are extensively used in different categories of heavy machinery found in construction, mining, and agriculture, showcasing their versatility and robustness.

- Food Processing and Packaging: The sprockets play a vital role in food processing and packaging machinery, including conveyor systems and filling and labeling machines, ensuring efficient operations.

- Chemical and Pharmaceutical: In the chemical and pharmaceutical sectors, these sprockets are essential components in equipment such as mixing machines and tablet presses, contributing to reliable processing.

- Assembly Lines: Found throughout assembly line machinery, these sprockets facilitate the movement and handling of products, thus streamlining production processes.

- Logistics and Warehousing: In logistics and warehouse operations, the FBN100B sprockets are utilized in conveyor systems and automated equipment, optimizing workflow and efficiency.

Maintenance and Troubleshooting

To ensure the long-term reliability of the FBN100B sprocket, regular maintenance and troubleshooting practices are necessary.

- Daily Inspection: Routine inspections are crucial and should include checking the sprocket for potential wear, damage, or misalignment. Promptly addressing any identified issues is important to prevent further damage to the system.

- Cleaning: Maintaining cleanliness by regularly removing dirt, debris, or other contaminants is essential, as this helps prevent any wear or damage to the sprocket.

- تشحيم: Proper lubrication is key to minimizing friction and wear between the sprocket and chain. Following the manufacturer's guidelines for lubrication frequency and type is critical.

- Adjustment and Calibration: Ensuring that adjustments are made correctly allows the sprocket and chain to function efficiently. Any misalignment issues should be corrected immediately to prevent operational issues.

Common concerns with sprockets may involve problems such as tooth skipping, breakage, wear, unwanted noise, and chain derailment. These issues often stem from improper installation, inadequate lubrication, or incorrect chain tension, and the solutions will vary based on the specifics of the problem encountered.

Other Types of Sprockets and Chains

In addition to the FBN100B Asian Standard finished bore sprocket, a variety of other sprocket types are available, including taper lock sprockets, QD sprockets, and idler sprockets, accompanying a diverse selection of chains.

Sprockets Supplier in the Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, a prestigious manufacturer known for producing high-quality mechanical components. Our product lineup includes the FBN100B Asian Standard Finished Bore Sprocket, engineered for exceptional performance and durability across various applications. Beyond our standard offerings, we provide custom solutions tailored to meet the distinctive requirements of our clients. Whether specific dimensions or unique designs are needed, our experienced team is prepared to assist with custom orders based on your specifications. We encourage all customers to get in touch for personalized sprocket solutions.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...