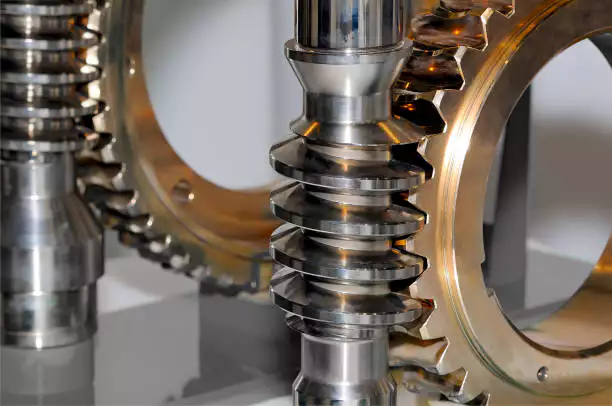

The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Electric Worm Gear

The Electric Worm Gear is a specialized mechanical device designed for precise motion control. Made from high-quality materials such as aluminum and steel, it ensures durability and efficiency. The primary function of the Electric Worm Gear is to reduce speed while increasing torque, making it ideal for various applications in automation and machinery.

Details of Electric Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 5:1 |

| Input Power | 500 W |

| Efficiency | 90% |

| Output Torque | 30 Nm |

| Operating Temperature | -10 to 60 °C |

| Weight | 2.5 kg |

| Material | Aluminum Alloy |

Key Features of Electric Worm Gear

- High Efficiency: Electric Worm Gear systems are designed for optimal performance, minimizing energy loss while maximizing torque output. Their unique gear design ensures smooth operation, making them ideal for various applications.

- Compact Size: The compact nature of Electric Worm Gear allows for easy installation in tight spaces, offering versatility in design without sacrificing power.

- Low Maintenance: With fewer moving parts compared to other gear systems, Electric Worm Gear requires less maintenance, leading to reduced downtime and costs.

Applications of Electric Worm Gear in Modern Machinery

The Electric Worm Gear is essential in various industrial applications, providing reliable and efficient motion control. Its unique design allows for high torque transmission and compact installation, making it ideal for use in conveyor systems, robotic arms, and automotive components. The Electric Worm Gear's smooth operation and ability to handle heavy loads ensure optimal performance in demanding environments. With its versatility and durability, the Electric Worm Gear plays a crucial role in enhancing the functionality of modern machinery.

Manufacturing Process of Electric Worm Gear

- Material Selection: The first step in the manufacturing process of the Electric Worm Gear involves selecting high-quality materials. Typically, robust metals such as bronze or hardened steel are chosen for their durability and strength. The choice of material impacts the gear's efficiency and longevity, ensuring it can withstand the heavy loads and high torque levels typically associated with electric drives. Additionally, the material's resistance to wear is crucial, as it affects the performance of the Electric Worm Gear over time.

- Machining: In this stage, the selected materials are precisely machined to achieve the desired shape and size of the Electric Worm Gear. Advanced CNC machines are often utilized to ensure accuracy and consistency. This process includes cutting, grinding, and shaping the gears to their specifications. Attention to detail during machining is essential, as any deviation can lead to inefficient operation and increased wear. Precision in creating the worm and gear teeth is critical for smooth engagement and transmission of power.

- Heat Treatment: After machining, the Electric Worm Gear undergoes heat treatment to enhance its mechanical properties. This process involves heating the gear to a specific temperature and then cooling it rapidly. Heat treatment increases the hardness and strength of the gear while also ensuring it maintains flexibility. This step is vital for the gear's resilience under stress, allowing it to function effectively in various applications. Properly heat-treated Electric Worm Gears can operate within a broader range of temperatures and loads.

- Assembly: The assembly of the Electric Worm Gear is a meticulous process that involves fitting the worm and gear together. This step requires precision to ensure proper alignment and function. The components are often tested for fit and movement before final assembly. Additionally, lubrication is applied to minimize friction and wear during operation. The assembly of the Electric Worm Gear must be executed carefully, as any misalignment can lead to premature failure and inefficiency in power transmission.

- ضبط الجودة: Finally, the finished Electric Worm Gear undergoes rigorous quality control checks. This includes testing for dimensional accuracy, load capacity, and operational efficiency. Various testing methods, such as torque tests and wear simulations, are employed to ensure the gear meets industry standards. Quality control is critical in the manufacturing of Electric Worm Gears, as it ensures that the final product is reliable and performs well in its intended applications, reducing the risk of failures in the field.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands.

Our product offerings include:

- High-quality electric worm gears designed for durability and efficiency.

- Products that undergo rigorous testing to ensure superior performance and reliability.

- A strong commitment to customer service, providing expert support and timely delivery.

- Innovative solutions tailored to meet various industrial requirements.

With our extensive experience and dedication to excellence, RP Techniek BV stands out in the market as a trusted supplier of worm gears.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...