In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

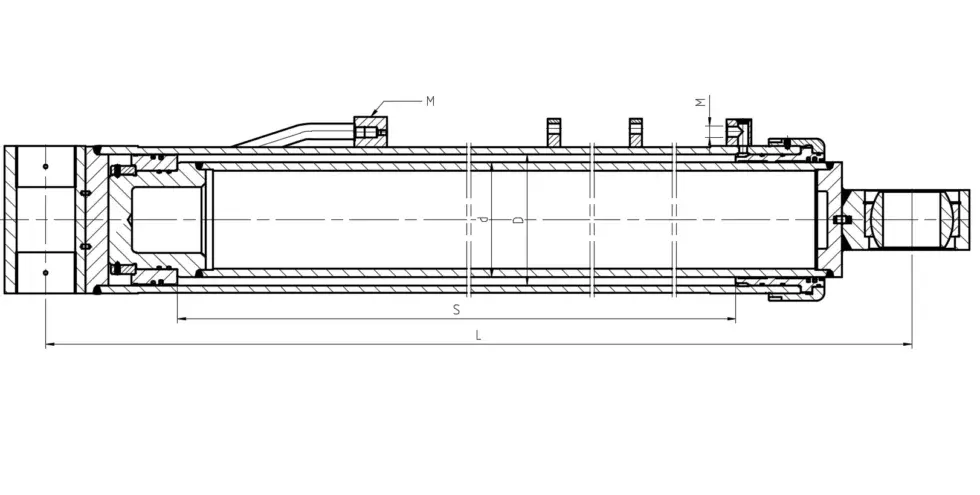

Crane Luffing Hydraulic Cylinder Technical Specification

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | ضغط العمل | Interface dimensions (M) | Weight |

| Luffing hydraulic cylinder | ZXSTC1000S.2.5-00 | Φ320 | Φ280 | 4000 | 4750 | 32MPa | 2-M27*2;4-G1/4 | 1522kg |

| غرض | Description |

| Product Name | Custom-made hydraulic Cylinder |

| Certificate: | ISO9001, ISO4001, ISO 45003 |

| Production Capacity: | 1200,000 pcs per year |

| Sample Time | Based actual type |

| Brand | EPT or customer's logo |

| Service | OEM & ODM |

| Seal brand | Parker,NOK, BUSAK SHAMBAN |

| Delivery Time | Based on order quantity. |

| Business Type | Manufacturer & Exporter |

Structure and Working Principle of Crane Luffing Cylinder

Crane luffing cylinder usually consists of the following parts:

- Cylinder body: made of high-strength steel, with good abrasion resistance and corrosion resistance, able to withstand greater pressure.

- Cylinder piston: controls the cylinder expansion and amplitude, the quality and performance of its seals directly affect the service life and safety performance of the cylinder.

- Seals: Ensure the sealing performance of the cylinder and prevent the hydraulic oil from leaking.

- Oil pipe: Connecting the cylinder and pump, conveying hydraulic oil.

The working principle is to control the luffing work through the luffing mechanism. The hydraulic oil is delivered from the oil pump to the oil cylinder, so that the piston extends and retracts outward, thus realizing the luffing function of the crane.

The control mode of the luffing mechanism has two kinds: manual and electric. Manual control requires the operator to use the handle, while the electric control is realized by controlling the solenoid valve through the electrical signal.

Crane Luffing Cylinder Types and Application Scenarios

Types of luffing cylinders include:

- Double-acting piston cylinder: The most common application, there are two oil ports. When the A port takes in oil, the B port returns the oil. The piston reciprocating movement depends on the action of the pressure oil.

- Single-acting piston cylinder: There is only one oil port. The pressure oil supplies oil to one side, and the plunger moves in one direction under pressure, while the return stroke is driven by gravity.

- Double-acting two-stage telescopic cylinder: Complex structure, suitable for large cranes.

Application scenarios mainly include:

- Small wheeled cranes: Usually use single-cylinder type luffing cylinders, which provide less thrust but are easy to adjust and maintain.

- Medium and large wheeled cranes: Use double-cylinder luffing cylinders, which provide large thrust, improve the lateral force of the lifting arm, and are mostly used in medium and large cranes.

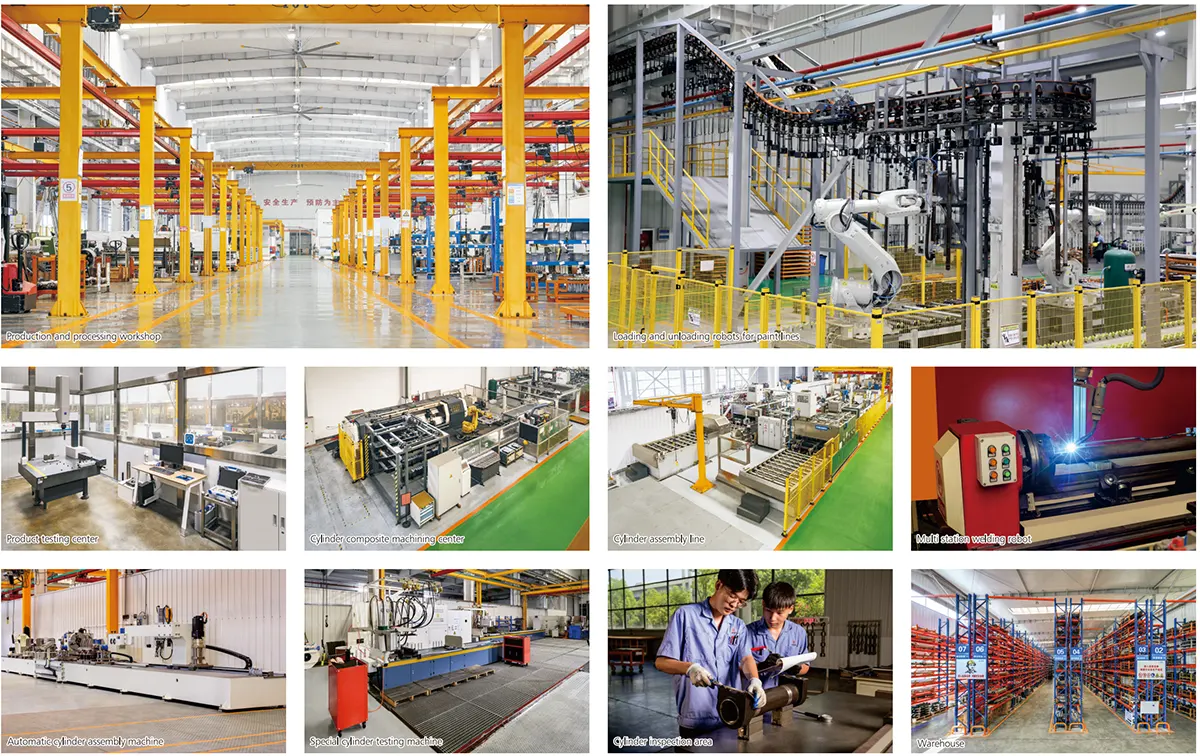

Crane Hydraulic Cylinders Manufacturer

Techniek BV is the sales agent for Ever-power Group, a company renowned for its excellence in manufacturing high-quality hydraulic systems. Our strength lies in our commitment to innovation and customer service, ensuring that we meet the specific needs of our clients with precision and expertise. We specialize in the production of Crane Luffing Hydraulic Cylinders, which are designed to provide superior performance and reliability in demanding applications.

In addition to our standard offerings, we proudly provide customized hydraulic cylinders, tailored to meet the unique requirements of our customers. We can produce non-standard cylinders with a diameter of D360MM and a stroke length of L6000MM, ensuring that we can accommodate a wide range of applications. We invite our esteemed clients to bring their drawings and samples for bespoke cylinder manufacturing, allowing us to deliver solutions that perfectly fit their operational needs.

معلومات إضافية

| Edited by | Sylvia |

|---|

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...