مقدمة

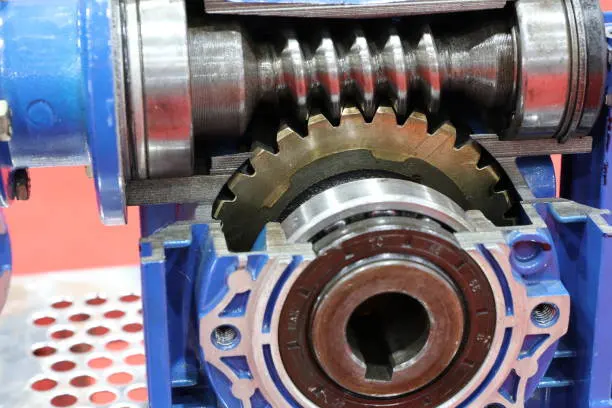

The assembly process of EPRV Series Small Worm Gearboxes requires attention to detail and precision to ensure optimal performance and longevity. In this article, we will explore some of the common assembly mistakes that can occur during the installation of these gearboxes. By understanding these mistakes, you can avoid potential issues and optimize the performance of your EPRV Series Small Worm Gearboxes.

Table of Contents

- Section 1: Improper Lubrication

- Section 2: Incorrect Gear Meshing

- Section 3: Misalignment of Shafts

- Section 4: Insufficient Torque

- Section 5: Inadequate Cooling

- Section 6: Overloading the Gearbox

- Section 7: Poor Quality Control

- Section 8: Conclusion

Section 1: Improper Lubrication

Proper lubrication is essential for the smooth operation of EPRV Series Small Worm Gearboxes. Insufficient or improper lubrication can lead to increased friction, wear, and potential damage to the gearbox components. It is recommended to use high-quality lubricants specifically designed for worm gear applications. Regular lubrication maintenance should be performed according to the manufacturer's guidelines to ensure optimal performance.

Section 2: Incorrect Gear Meshing

Proper gear meshing is crucial for the efficient transfer of power in EPRV Series Small Worm Gearboxes. Incorrect gear meshing can result in increased noise, vibration, and decreased overall performance. It is important to carefully align the gears during assembly and ensure proper tooth engagement. Regular inspection and adjustment of gear meshing should be performed to maintain optimal performance.

Section 3: Misalignment of Shafts

Shaft misalignment can significantly impact the performance and lifespan of EPRV Series Small Worm Gearboxes. It can cause increased stress on the gears and bearings, leading to premature wear and failure. During assembly, it is essential to carefully align the input and output shafts to ensure proper alignment. Regular monitoring of shaft alignment should be conducted to prevent any potential issues.

Section 4: Insufficient Torque

Applying insufficient torque during assembly can result in loose connections and inadequate power transmission in EPRV Series Small Worm Gearboxes. It is crucial to follow the manufacturer's recommended torque specifications for all fasteners to ensure proper tightening. Regular inspection of fasteners should be performed to maintain optimal torque and prevent any potential issues.

Section 5: Inadequate Cooling

Proper cooling is essential to prevent overheating and ensure the longevity of EPRV Series Small Worm Gearboxes. Inadequate cooling can lead to increased operating temperatures, which can degrade lubricants and accelerate wear. It is important to ensure proper ventilation and, if necessary, utilize additional cooling mechanisms such as fans or heat sinks. Regular monitoring of gearbox temperature should be conducted to prevent overheating.

Section 6: Overloading the Gearbox

Overloading the gearbox beyond its designed capacity can cause excessive stress on the components and lead to premature failure. It is crucial to understand the maximum load capacity of EPRV Series Small Worm Gearboxes and operate within the recommended limits. Regular monitoring of operating conditions and loads should be performed to prevent overloading and ensure optimal performance.

Section 7: Poor Quality Control

Poor quality control during the manufacturing process can result in various assembly mistakes with EPRV Series Small Worm Gearboxes. It is essential to choose a reputable manufacturer with a strong quality control system in place. Regular inspection and testing of gearbox components should be conducted to ensure that they meet the required standards and specifications.

Section 8: Conclusion

In conclusion, the assembly process of EPRV Series Small Worm Gearboxes requires attention to detail and adherence to proper assembly techniques. By avoiding common assembly mistakes such as improper lubrication, incorrect gear meshing, shaft misalignment, insufficient torque, inadequate cooling, overloading, and poor quality control, you can maximize the performance and lifespan of these gearboxes. Regular maintenance and monitoring are essential to ensure optimal performance and prevent potential issues.

محركات كهربائية للبيع

Electric motors and gearboxes are interdependent components in various applications. The gearbox converts the motor's high-speed, low-torque rotational motion into low-speed, high-torque output, which is suitable for different machinery requirements. At Ever-power Group, we also provide a wide range of electric motors for sale, complementing our gearbox offerings.

معلومات عنا

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We specialize in the production and sales of high-quality worm gearboxes. With over 25 years of experience, we have established a strong reputation in the market, serving customers in Europe, America, Africa, Asia, and more. Our commitment to providing the best service, highest product quality, and competitive prices has earned us the trust and loyalty of our customers.

We are a comprehensive transmission equipment manufacturer, integrating research and development, manufacturing, and sales of speed reducers. Our advanced production and testing equipment, along with our team of industry professionals and technicians, enable us to deliver innovative and reliable gearboxes. We strictly adhere to standardized production management methods to ensure the highest quality in every aspect of our gearbox manufacturing process.

Our gearboxes are widely used in various industries, including equipment, food, car washing, packaging, transmission, automation, solar energy, and more. We welcome customers to explore our products and contact us for purchasing inquiries.

الأسئلة والأجوبة

Q: Can EPRV Series Small Worm Gearboxes be used in high-temperature environments?

A: EPRV Series Small Worm Gearboxes are designed to operate within specific temperature ranges. It is important to consult the manufacturer's specifications to ensure the gearbox is suitable for high-temperature applications. In some cases, additional cooling mechanisms may be required to maintain optimal performance.

Q: Are EPRV Series Small Worm Gearboxes suitable for heavy-duty applications?

A: EPRV Series Small Worm Gearboxes have varying load capacities depending on the specific model. It is important to select a gearbox that matches the requirements of the application. For heavy-duty applications, it is recommended to choose a gearbox with a higher load capacity to ensure reliable and long-lasting performance.

Q: What maintenance is required for EPRV Series Small Worm Gearboxes?

A: Proper lubrication and regular inspection are key maintenance tasks for EPRV Series Small Worm Gearboxes. Lubrication should be performed according to the manufacturer's guidelines, and any signs of wear or damage should be addressed promptly. Regular monitoring of operating conditions and loads can also help identify potential issues before they escalate.

Q: Can EPRV Series Small Worm Gearboxes be mounted in any orientation?

A: EPRV Series Small Worm Gearboxes can generally be mounted in multiple orientations, including horizontal, vertical, or angled positions. However, it is important to consult the manufacturer's specifications to ensure proper mounting and maintain optimal performance.

Q: Can EPRV Series Small Worm Gearboxes be customized to specific requirements?

A: Customization options may be available for EPRV Series Small Worm Gearboxes, depending on the manufacturer's capabilities. It is recommended to discuss your specific requirements with the manufacturer to determine the feasibility of customization.

تم تحريره بواسطة: Zqq.