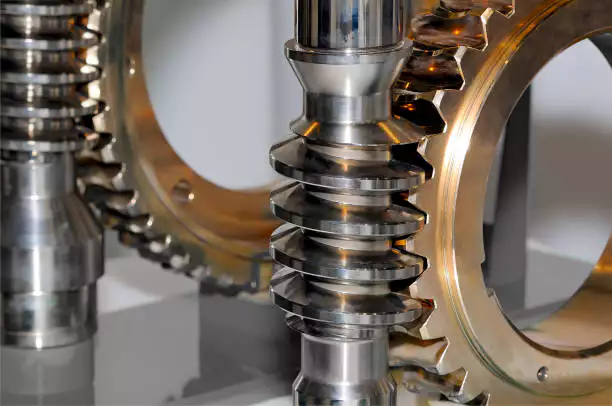

The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear Shaft

The Worm Gear Shaft is a crucial component in various mechanical systems, designed to transmit torque and motion efficiently. Made from high-strength steel or aluminum, it ensures durability and reliability. The Worm Gear Drive Shaft plays a significant role in reducing speed and increasing torque, making it essential for applications requiring precise control.

Details of Worm Gear Shaft

| Parameter | Value |

|---|---|

| Material | Alloy Steel |

| Diameter | 25 mm |

| Length | 100 mm |

| Pitch | 2 mm |

| Number of Teeth | 10 |

| Load Capacity | 500 N |

| Efficiency | 90% |

| Operating Temperature | -20 to 100 °C |

Features of the Worm Gear Shaft

- High Efficiency: The Worm Gear Drive Shaft is designed to provide smooth and efficient power transmission, minimizing energy loss during operation.

- Compact Design: Its compact structure allows for installation in tight spaces, making it ideal for various applications without sacrificing performance.

- Self-Locking Mechanism: The unique design of the Worm Gear Shaft ensures that it can hold a load without requiring additional brakes, enhancing safety.

- Versatile Applications: The Worm Gear Drive Shaft is suitable for a wide range of industrial applications, including conveyor systems and robotics.

How Worm Gear Shafts Operate

The Worm Gear Shaft is a critical component in the worm gear drive system, which allows for the efficient transfer of motion and torque. This mechanism utilizes a worm screw that meshes with a gear, providing a significant mechanical advantage in reducing speed while increasing torque. The unique design of the Worm Gear Drive Shaft facilitates smooth operation and minimizes backlash, making it ideal for various applications, including machinery and automotive systems. Understanding the functionality of the Worm Gear Shaft is essential for optimizing performance in gear systems.

Manufacturing Process of Worm Gear Shaft

- Material Selection: The manufacturing of the Worm Gear Shaft begins with selecting the right materials. Typically, high-strength steel or alloy materials are chosen to ensure durability and resistance to wear. The selected material influences the overall performance of the Worm Gear Drive Shaft, affecting its strength and longevity. High-quality materials minimize the risk of deformation and ensure that the shaft can withstand the operational stresses encountered during use.

- Machining: Once the material is selected, the next step involves precise machining of the Worm Gear Shaft. This process includes turning, milling, and grinding to achieve the desired dimensions and surface finish. The machining ensures that the gear teeth are accurately formed and that the shaft is smooth, which is crucial for efficient operation. Proper machining also contributes to the alignment and meshing characteristics of the Worm Gear Drive Shaft, enhancing its performance.

- Heat Treatment: After machining, the Worm Gear Shaft undergoes heat treatment to improve its mechanical properties. This process typically involves hardening and tempering, which enhances the strength and durability of the shaft. Heat treatment helps to relieve internal stresses and ensures that the Worm Gear Drive Shaft can perform under high loads without failing. Different heat treatment processes can be applied depending on the specific requirements of the application.

- Testing and Quality Control: Finally, rigorous testing and quality control measures are applied to ensure that the Worm Gear Shaft meets industry standards. This includes dimensional checks, hardness tests, and performance evaluations. Quality control ensures that the Worm Gear Drive Shaft operates efficiently and safely within its intended application. Any defects detected during this stage are addressed before the product is finalized and shipped to customers.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country.

Our product offerings include:

- Worm Gear Shafts: Manufactured with precision to ensure optimal performance and durability.

- Unmatched Quality: We uphold the highest standards of quality and craftsmanship, ensuring longevity in all our products.

- Strong Reputation: Our experience in the industry has established us as a reliable partner for businesses seeking the best in worm gear technology.

- Comprehensive Service: We provide exceptional customer support, from product selection to after-sales service, catering to all your needs.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...