The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Plastic Worm Gears

Plastic worm gears are essential mechanical components designed for efficient power transmission. Made from durable plastic, these gears provide lightweight solutions in various applications. A plastic worm gear set typically includes a plastic worm wheel and small plastic worm gears, ensuring smooth operation and reduced friction in machinery using a plastic worm drive.

Details of Plastic Worm Gears

| Parameter | Value |

|---|---|

| Material | Plastic |

| Gear Ratio | 10:1 |

| Diameter | 20 mm |

| Length | 30 mm |

| Weight | 15 g |

| Temperature Range | -20 to 80 °C |

Features of Plastic Worm Gears

- Durability: Plastic worm gears are designed to withstand wear and tear, making them suitable for various applications. Their robust nature ensures longevity, especially in environments where metal gears may corrode.

- Lightweight: Small plastic worm gears provide a significant advantage in applications where weight is a concern. Their lightweight nature contributes to overall efficiency without compromising strength.

- Noise Reduction: The plastic material used in plastic worm drive systems helps to minimize operational noise, making them ideal for quiet machinery setups.

- Cost-Effectiveness: Utilizing a plastic worm gear set can be more economical than metal alternatives, reducing production costs while maintaining functional integrity.

How Plastic Worm Gears Work

Plastic worm gears are essential components in mechanical systems, providing efficient torque conversion and motion transmission. A typical plastic worm drive consists of a plastic worm gear that meshes with a plastic worm wheel, creating a unique gear ratio. This design is ideal for various applications, as small plastic worm gears offer high precision and durability. A complete plastic worm gear set can significantly enhance performance in machinery, ensuring smooth operation and reliability. The lightweight nature of these plastic components makes them suitable for a range of industries.

Manufacturing Process of Plastic Worm Gears

- Material Selection: The manufacturing process of plastic worm gears begins with selecting high-quality thermoplastic materials. These materials are chosen for their strength, durability, and resistance to wear. The appropriate plastic ensures that the plastic worm drive functions efficiently under various conditions. The right choice of plastic is crucial for creating a reliable plastic worm gear set that can withstand the mechanical stresses experienced during operation.

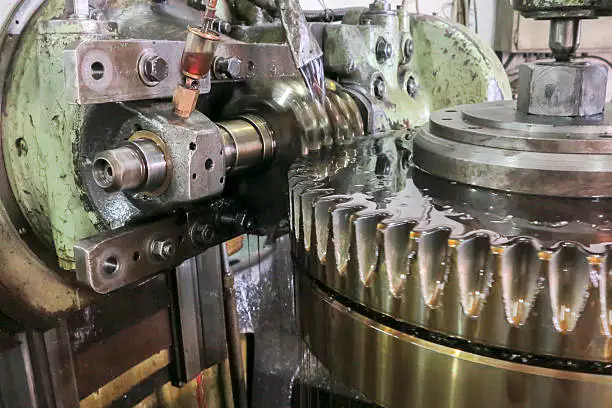

- Injection Molding: Once the material is selected, the next step is the injection molding process. In this stage, the thermoplastic is heated until it reaches a molten state and then injected into molds that define the shape of the plastic worm gear and plastic worm wheel. This process allows for precise manufacturing of small plastic worm gears, ensuring that they fit perfectly within the gear system. The accuracy in this stage is essential for the efficiency of the entire drive system.

- Cooling and Ejection: After the injection molding, it's important to allow the molded components to cool down. This cooling process solidifies the plastic, allowing the plastic worm gears to retain their shape. Once cooled, the gears are ejected from the mold. Proper cooling is critical to avoid warping and ensure the dimensional accuracy of the plastic worm gear set, which is vital for optimal performance.

- Finishing Processes: The final step includes various finishing processes such as trimming, machining, and surface treatment. These processes help remove any excess material and ensure the smooth operation of the plastic worm gears. Surface treatments may be applied to enhance wear resistance and decrease friction between the plastic worm drive components. This ensures longevity and reliability in applications requiring precise movements.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country.

Our product range includes high-quality plastic worm gears that are designed to meet the needs of various industries. Here are some key points about our offerings:

- Top-notch quality: We ensure that all our products are manufactured to the highest standards, providing durability and reliability.

- Exceptional craftsmanship: Our plastic worm gears are crafted with precision, ensuring optimal performance in all applications.

- Strong expertise: With years of experience in the industry, we have the knowledge and skills to deliver tailored solutions to our clients.

- Comprehensive service: We pride ourselves on providing excellent customer service, from initial consultation to after-sales support.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...