The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Industrial Gearboxes

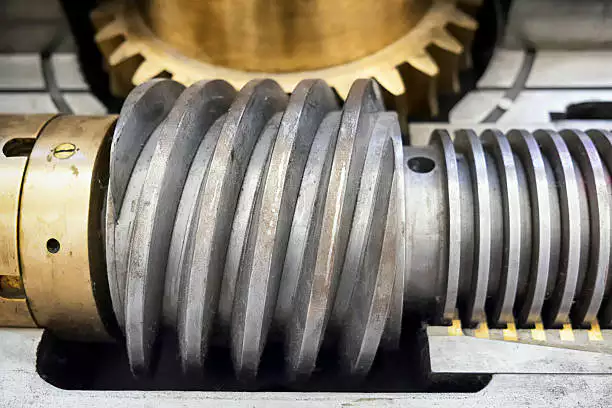

The worm gear in industrial gearboxes is a crucial component designed for efficient power transmission. This type of gear provides a unique mechanism that allows for high torque and low-speed operation, making it ideal for various applications. In gearbox systems, the worm gear for power transmission ensures smooth and reliable functionality. Its uses extend to heavy-duty gearboxes, where it can handle significant loads. Overall, the worm gear in gearboxes enhances performance and durability in industrial settings.

Specifications of Worm Gear in Industrial Gearboxes

| Specification | Details |

|---|---|

| Gear Ratio | 10:1 |

| Material | Bronze |

| Load Capacity | 500 Nm |

| Efficiency | 85% |

| Operating Temperature | -10 to 100 °C |

| Mounting Type | Horizontal/Vertical |

Why Worm Gears are Suitable for Worm Gear in Industrial Gearboxes

Worm gears are ideal for use in industrial gearboxes due to their unique design and advantages. Here are several reasons:

- High Torque Transmission: The worm gear in industrial gearboxes allows for effective power transmission, providing high torque in compact spaces.

- Self-Locking Feature: Worm gears can prevent back-driving, making them suitable for applications requiring safety and stability in gearbox systems.

- Versatility: The industrial gearbox worm gear uses include heavy-duty applications where reliability is crucial.

- Smooth Operation: Worm gear in gearboxes offers quiet and smooth operation, essential for various industrial applications.

- Space Efficiency: These gears are designed for tight spaces, making them perfect for heavy-duty gearboxes.

How Worm Gears Work in Industrial Gearboxes

Worm gears in industrial gearboxes play a crucial role in power transmission, offering high torque and minimal backplay. The unique design of a worm gear, consisting of a screw (the worm) and a gear (the worm wheel), allows for efficient rotation and significant gear reduction. In gearbox systems, these worm gears enable smooth operation, especially in heavy-duty gearboxes where durability is essential. The use of worm gear in gearboxes not only enhances performance but also ensures longevity, making them ideal for various industrial applications. Industrial gearbox worm gear uses are widespread, providing reliable solutions for machinery that demands precision and strength.

Manufacturing Process of Worm Gear in Industrial Gearboxes

- Material Selection: The manufacturing process of a worm gear in industrial gearboxes begins with the selection of suitable materials. High-quality materials, such as alloyed steel or bronze, are chosen for their durability and strength. These materials are crucial for ensuring the worm gear in gearboxes can withstand the heavy loads and stress during operation. Proper material selection influences the performance and longevity of worm gears in heavy-duty gearboxes, making it a fundamental step in the production process.

- CNC Machining: After material selection, CNC (Computer Numerical Control) machining is employed to shape the worm gear accurately. This process allows for precision cutting and shaping of the gear teeth, ensuring that the worm gear for power transmission fits perfectly within the gearbox system. CNC machining enhances the efficiency of the manufacturing process, resulting in high-quality worm gears that meet the specific requirements of various industrial applications.

- Heat Treatment: Heat treatment is a critical stage in the production of worm gears in industrial gearboxes. This process involves heating the machined gears to enhance their hardness and wear resistance. The heat treatment process not only improves the mechanical properties of the worm gear but also ensures its reliability during heavy-duty operations. Properly treated worm gears can significantly reduce failure rates, thus extending the lifespan of gearbox systems.

- Surface Finishing: Surface finishing is essential for minimizing friction and wear in worm gear in gearbox systems. This step may include grinding, polishing, or coating the gears to achieve a smooth surface finish. A well-finished worm gear in gearboxes reduces energy loss and improves efficiency during power transmission. The surface quality directly impacts the performance of industrial gearbox worm gear uses, making this an important aspect of the manufacturing process.

- ضبط الجودة: The final step in the manufacturing process involves rigorous quality control measures. Each worm gear in industrial gearboxes undergoes testing to ensure that it meets the required specifications and standards. This may involve dimensional checks, performance tests, and inspections for any defects. Quality control is crucial to guarantee that the worm gear functions optimally in gearbox systems, providing reliable and effective power transmission in various industrial applications.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for the Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands. We pride ourselves on delivering high-quality products tailored to meet diverse industrial requirements.

- Exceptional Quality: Our worm gears are manufactured using top-grade materials, ensuring durability and reliability in various applications.

- Superior Performance: Designed for efficiency, our products contribute to optimal performance in industrial gearboxes, reducing wear and tear.

- Strong Expertise: With years of experience in the industry, our team is well-equipped to provide expert advice and support to our clients.

- Comprehensive Service: We offer outstanding customer service, ensuring timely delivery and assistance with any queries or concerns.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...