The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Conveying Engineering

Worm gears are crucial components in conveying engineering, providing efficient torque and speed reduction in various conveying systems. The worm gear in conveying engineering allows for smooth movement and precise control of materials, making it an ideal choice for industrial applications. These gears are commonly utilized for material transport, ensuring reliable operation even under heavy loads. The conveying engineering worm gear uses contribute to enhanced performance and durability, while the industrial worm gear for conveying systems facilitates the design of advanced conveyor technology.

Specifications of Worm Gear in Conveying Engineering

| Specification | Details |

|---|---|

| Gear Ratio | 5:1 to 100:1 |

| Material | Aluminum, Steel, Bronze |

| Load Capacity | 100 kg to 1000 kg |

| Efficiency | 75% to 90% |

| Output Torque | 10 Nm to 500 Nm |

| Operating Temperature | -20°C to 100°C |

Why Worm Gears are Suitable for Worm Gear in Conveying Engineering

Worm gears are ideal for conveying engineering applications due to several key advantages:

- High Torque Transmission: They provide significant torque, making them effective in worm gear for material transport.

- Compact Design: Their space-saving design is perfect for conveying systems where space is limited.

- Efficiency: Worm gear in conveying systems offers smooth and quiet operation, enhancing overall efficiency.

- Durability: Industrial worm gear for conveying is built to withstand heavy loads, ensuring long-lasting performance.

- Versatility: They can be used in various applications, showcasing the diverse conveying engineering worm gear uses.

How Worm Gears Work in Conveying Engineering

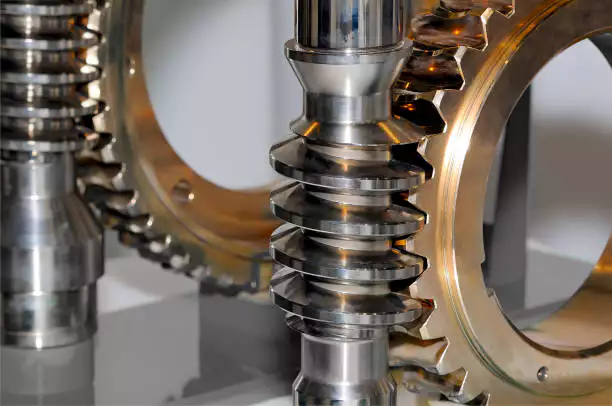

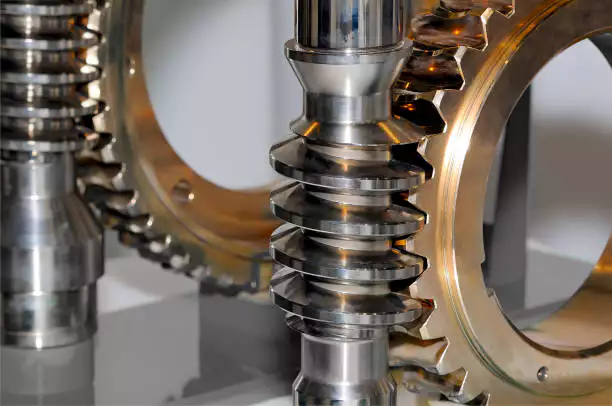

Worm gears play a crucial role in conveying engineering by providing efficient power transmission and high torque. In conveying systems, the unique design of the worm gear allows for smooth operation, making it ideal for various applications. The worm gear in conveying engineering is specifically designed to handle heavy loads and ensure material transport with minimal slippage. Industrial worm gears are commonly used for conveying, where their compact size and ability to reduce speed while increasing torque make them perfect for conveyor technology. By utilizing a worm gear for material transport, industries can achieve reliable and efficient movement of goods. Below is an illustration of a worm gear and its shaft:

Manufacturing Process of Worm Gear in Conveying Engineering

- Design and Engineering: The manufacturing process begins with the design of the worm gear in conveying engineering. Engineers utilize computer-aided design (CAD) software to create precise models that define the dimensions and specifications required for optimal performance in conveying systems. The design phase incorporates considerations for load capacity, speed, and efficiency, ensuring that the worm gear can effectively function in material transport applications within industrial settings. Such careful planning is crucial to meet the standards of modern conveying engineering, ensuring longevity and reliability.

- Material Selection: Choosing the right materials is essential in the production of a worm gear for material transport. Common materials include high-strength alloys and heat-treated steel, which provide the necessary durability and resistance to wear. The selection process focuses on the intended application within conveying systems, where factors like corrosion resistance and load-bearing capacity come into play. The right material enhances the performance of the industrial worm gear for conveying, ensuring that it can withstand the demands of heavy-duty operations.

- Manufacturing Techniques: The manufacturing of worm gears employs various techniques such as precision casting, machining, and grinding. These processes ensure the components are manufactured to exact specifications, facilitating smooth interactions between the worm and the gear. Advanced technologies like CNC machining are often utilized to achieve high precision and repeatability in the production of components. This level of detail is vital in conveyor technology, where the efficiency and effectiveness of material transport depend on the seamless integration of all parts.

- Assembly and Testing: Once individual components are manufactured, they are assembled to form the complete worm gear in conveying engineering. During assembly, attention is paid to alignment and fitting to prevent operational issues. After assembly, rigorous testing is conducted to ensure the gear operates efficiently under various loads and conditions. This step is crucial, as it verifies the performance of the worm gear in conveyor technology and ensures it meets industry standards for quality and reliability.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands. Our commitment to excellence and innovation sets us apart in the industry.

In the realm of conveying engineering, our worm gear products are designed to meet the highest standards. Key features include:

- Top-notch Quality: Our worm gears are manufactured with precision, ensuring durability and reliability in all applications.

- First-class Performance: Engineered for superior performance, our products facilitate efficient power transmission.

- Robust Strength: We provide gear solutions that can withstand heavy loads, enhancing operational efficiency.

- Exceptional Service: Our team is dedicated to providing outstanding customer support, ensuring your needs are met promptly.

With a strong reputation for quality and service, RP Techniek BV is your trusted partner for worm gear solutions.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...