The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Stainless Steel Worm Gear

The stainless steel worm gear is a precision mechanical component designed for high torque and low-speed applications. Made from durable stainless steel, this stainless worm gear ensures excellent corrosion resistance and longevity. Ideal for various industrial uses, the steel worm gear set provides reliable performance and efficient power transmission in demanding environments.

Details of Stainless Steel Worm Gear

| Parameter | Value |

|---|---|

| Material | Stainless Steel |

| Gear Type | Worm Gear |

| Gear Ratio | 10:1 |

| Load Capacity | 500 Nm |

| Operating Temperature | -20°C to 100°C |

| Surface Finish | Polished |

| Dimensions | 100 mm x 50 mm x 30 mm |

Features of Stainless Steel Worm Gear

- Corrosion Resistance: The stainless steel worm gear is designed to withstand harsh environments, ensuring longevity and reliability. Its stainless composition prevents rust and degradation, making it ideal for outdoor and marine applications.

- High Load Capacity: The robust design of the steel worm gear allows it to support heavy loads without compromising performance. This makes the stainless worm gear suitable for heavy machinery and industrial uses.

- Smooth Operation: A steel worm gear set provides efficient power transmission with minimal friction, resulting in quieter and smoother operation. This is essential for applications that require precision and reliability.

Working Principle of Stainless Steel Worm Gear

The stainless steel worm gear is a crucial component in various mechanical systems, providing efficient torque transmission and motion control. This type of gear set consists of a worm, resembling a screw, that engages with a worm wheel, allowing for smooth rotation. The use of stainless steel enhances durability and resistance to corrosion, making the stainless worm gear ideal for demanding environments. With its unique design, the steel worm gear ensures a high reduction ratio and compact size, which is advantageous in applications requiring tight space constraints. Overall, the steel worm gear set is essential for reliable and efficient machinery operation.

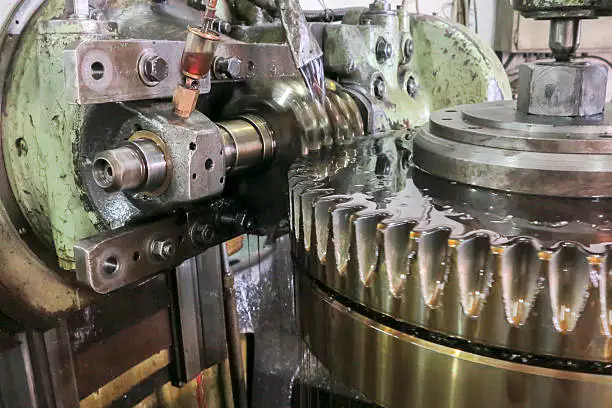

Manufacturing Process of Stainless Steel Worm Gear

- Material Selection: The first step in manufacturing stainless steel worm gears involves selecting the appropriate type of stainless steel. The chosen material must possess high corrosion resistance, durability, and strength to withstand the operational demands. Stainless steel is preferred for its ability to maintain performance in challenging environments. The stainless worm gear's composition is critical, influencing its longevity and functionality. Proper material selection ensures that the steel worm gear will perform efficiently in mechanical systems, enhancing reliability and reducing maintenance costs.

- Precision Machining: Once the stainless steel is sourced, the next phase is precision machining. This process involves cutting and shaping the stainless steel worm gear using advanced CNC machines. The accuracy of this machining process is vital to achieve the desired dimensions, surface finish, and tooth profiles of the steel worm gear. Any imperfections during this stage can lead to inefficiencies or failures in the gear set. Thus, maintaining tight tolerances and smooth finishes ensures optimal performance in the mechanical application of the stainless steel worm gear.

- Heat Treatment: After machining, the stainless steel worm gear undergoes heat treatment to enhance its mechanical properties. This process involves heating the gear to a specific temperature and then cooling it rapidly. Heat treatment increases the hardness and strength of the steel worm gear, making it more resistant to wear and fatigue. This step is crucial in extending the lifespan of the stainless worm gear, especially in applications that involve high torque and load-bearing conditions. The result is a robust steel worm gear set that can operate effectively under various stressors.

- Surface Finishing: The final stage in the manufacturing process is surface finishing. This step involves polishing and coating the stainless steel worm gear to improve its aesthetic appeal and protect it from environmental damage. Finishing techniques such as electroplating or anodizing may be applied to enhance corrosion resistance further. A well-finished stainless worm gear not only functions better but also has a longer lifespan. The surface finish also plays a role in reducing friction during operation, promoting smoother gear interactions within the steel worm gear set.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for the Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands. Our commitment to quality and innovation sets us apart in the industry.

Our product offerings include:

- Stainless Steel Worm Gears: Known for their durability and resistance to corrosion, making them ideal for various applications.

- Exceptional Quality: We maintain stringent quality control processes to ensure that every product meets high industry standards.

- Robust Service: Our experienced team is dedicated to providing excellent customer service, offering technical support and guidance tailored to your needs.

- Competitive Strength: As a reputable supplier, we leverage our strong relationships with manufacturers to deliver quality products at competitive prices.

معلومات إضافية

| Edited | Zqq |

|---|

تم تحديث المدونات

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...