In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

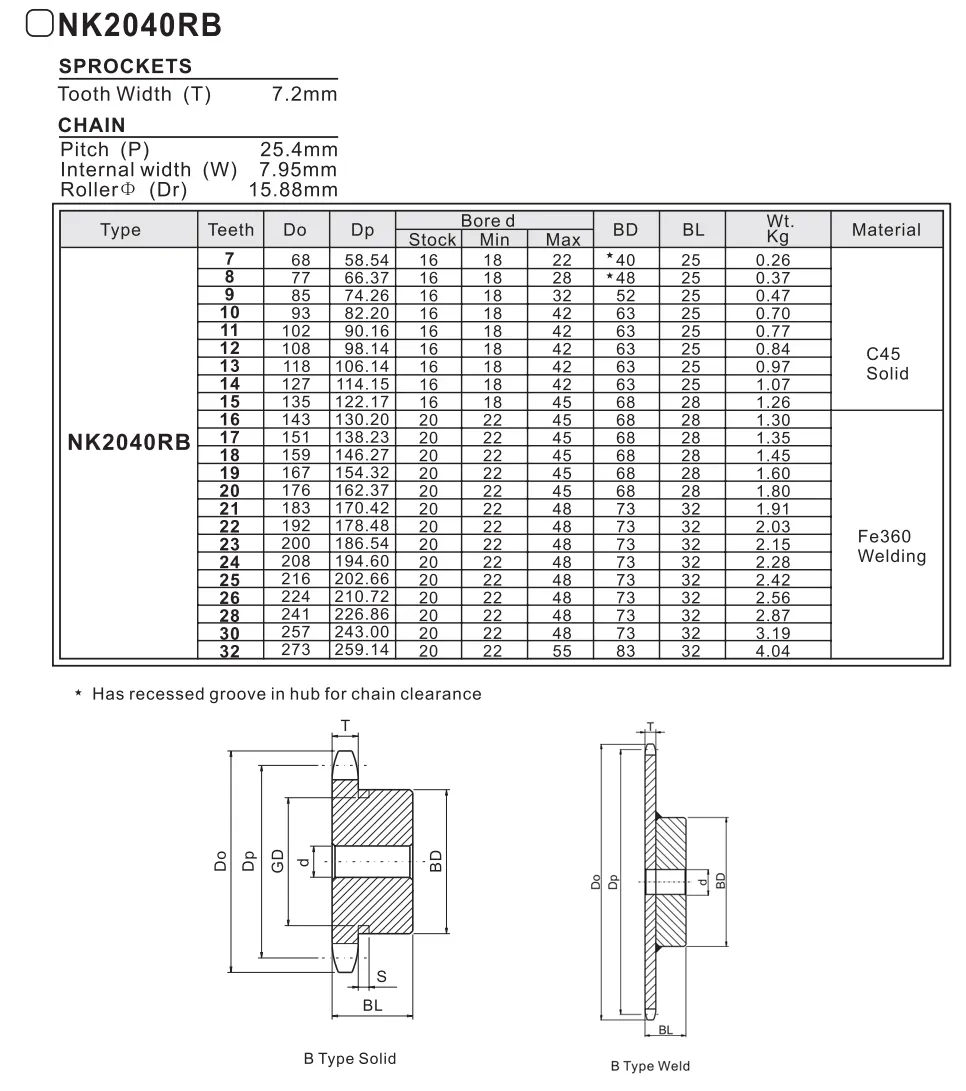

NK2040RB Double Pitch Sprocket

The NK2040RB Double Pitch Sprocket is engineered for durability and efficiency in power transmission. Designed for seamless integration with roller chains, it offers superior performance in various applications, ensuring reliable operation and extended service life in demanding environments.

Specifications of NK2040RB Double Pitch Sprocket

The NK2040RB Double Pitch Sprocket serves as an essential component in various transmission systems. Its unique design and functionality have led to widespread use in multiple industries, making it a preferred choice for many applications.

Definition and Basic Structure

The Double Pitch Sprocket is distinguished by its larger pitch diameter and elongated distances between its teeth when compared to conventional sprockets. This specialized design promotes smoother, more efficient power transmission, which is crucial for optimizing performance in various machinery.

Main Features

- Larger tooth spacing: The Double Pitch Sprocket provides a broader gap between its teeth, which significantly reduces the likelihood of chain jamming. This design enhancement contributes to improved overall performance and reliability.

- Higher load capacity: Built with robust materials, the Double Pitch Sprocket can sustain heavier loads without any compromise to its functionality or performance under stress.

- Smooth operation: Its thoughtful design ensures that the sprocket rotates smoothly, which results in lower noise levels and minimized vibrations during operation.

Material Selection

Double Pitch Sprockets are typically made from three main types of materials:

- Carbon steel: Known for its remarkable strength and durability, carbon steel sprockets are perfect for applications that experience moderate loads and demanding conditions.

- Alloy steel: These sprockets are designed to provide enhanced hardness and wear resistance, making them particularly suitable for heavy-duty and high-performance applications.

- Stainless steel: Valued for their corrosion resistance, stainless steel sprockets are often utilized in environments prone to moisture or chemical exposure.

Manufacturing Process

The production of our Double Pitch Sprockets adheres to a comprehensive manufacturing process that guarantees top-notch quality:

- Raw material preparation: Selected materials undergo meticulous preparation to meet the requirements of manufacturing.

- Forging or casting: Sprocket blanks are shaped using either forging or casting techniques.

- Machining: Precision machining is applied to the blanks to achieve the required dimensions and tooth profiles.

- Gear hobbing: Cutting of the sprocket teeth is performed using a gear hobbing machine to ensure accuracy.

- Heat treatment: Sprockets undergo heat treatment processes to enhance hardness and overall mechanical properties.

- Surface treatment: Various surface treatments, including plating or painting, are applied to improve corrosion resistance and enhance aesthetic appeal.

- Quality inspection: Every sprocket is subjected to thorough quality checks to verify compliance with industry standards and specifications.

Customization Services

We offer a variety of customization services tailored for our sprockets:

- Material selection: Customers have the option to choose materials that align perfectly with their specific application requirements.

- Tooth profile design: We provide customizable tooth profiles to enhance performance and ensure compatibility with the corresponding chain.

- Bore diameter and keyway: Custom options for bore diameters and keyways are available to accommodate various shaft sizes and coupling methods.

Sprockets Supplier in the Netherlands

RP Techniek BV serves as the official sales agent for Ever-Power Group, a renowned manufacturer that specializes in high-quality sprockets. Our portfolio includes the NK2040RB Double Pitch Sprocket, engineered to deliver superior performance and durability across multiple applications. This sprocket is meticulously designed to ensure smooth operations, effectively reducing wear and prolonging the life of your machinery.

In addition to our standard offerings, we take pride in providing custom solutions tailored to meet the unique needs of our clients. We encourage all customers to present their designs and samples for non-standard customization. Our dedicated team is focused on delivering exceptional products and services to fulfill your requirements.

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...