In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

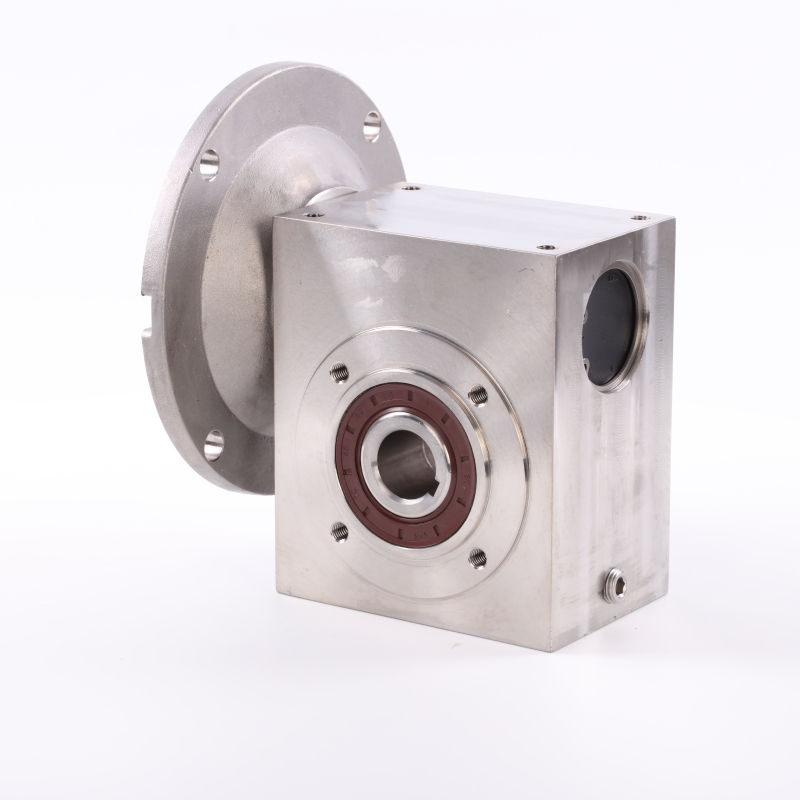

EP-GMSS Series Stainless Steel Worm Gearbox

The EP-GMSS Series Stainless Steel Worm Gearbox features a 304 precision cast housing, a 12-2 tin bronze worm wheel, a 304 worm core, and a fully synthetic worm gear oil. The gearbox is processed on all six sides, providing an aesthetically pleasing appearance and corrosion resistance. There are six models available, with sizes ranging from 30 to 90.

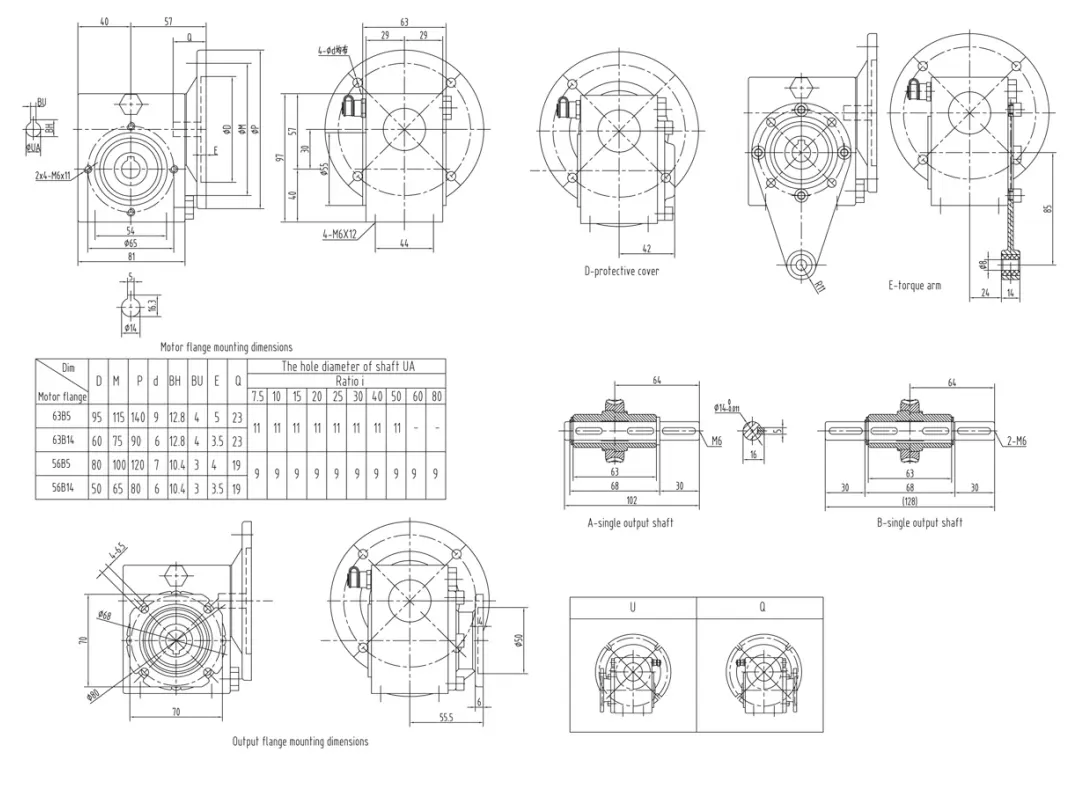

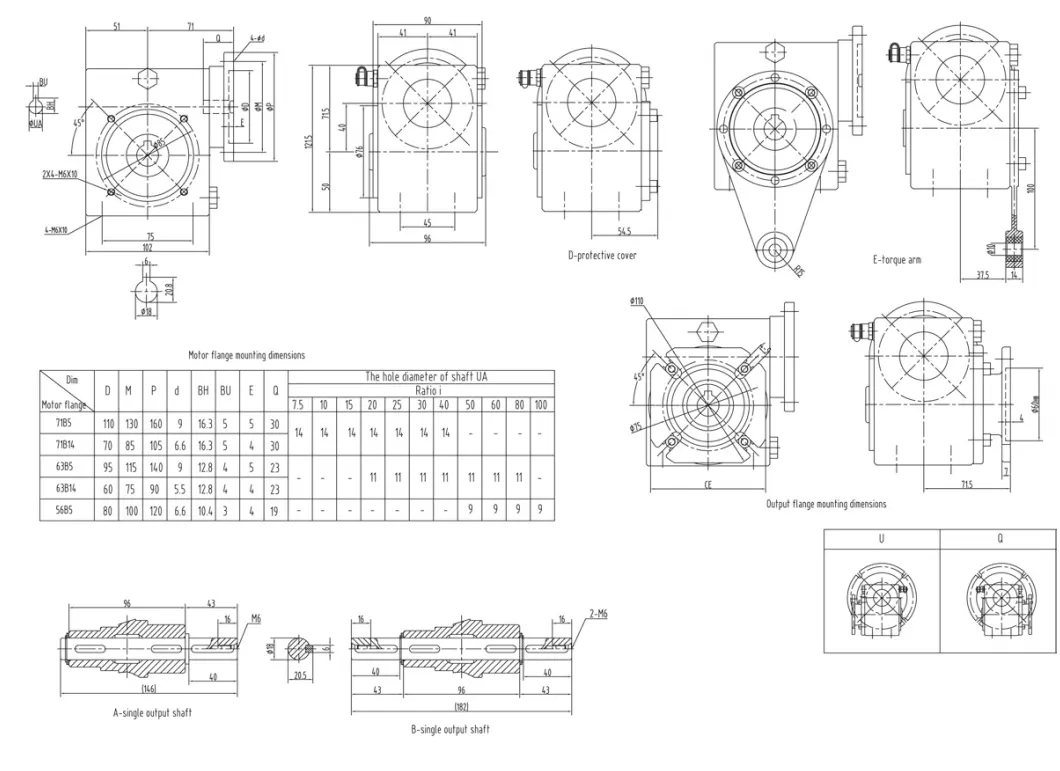

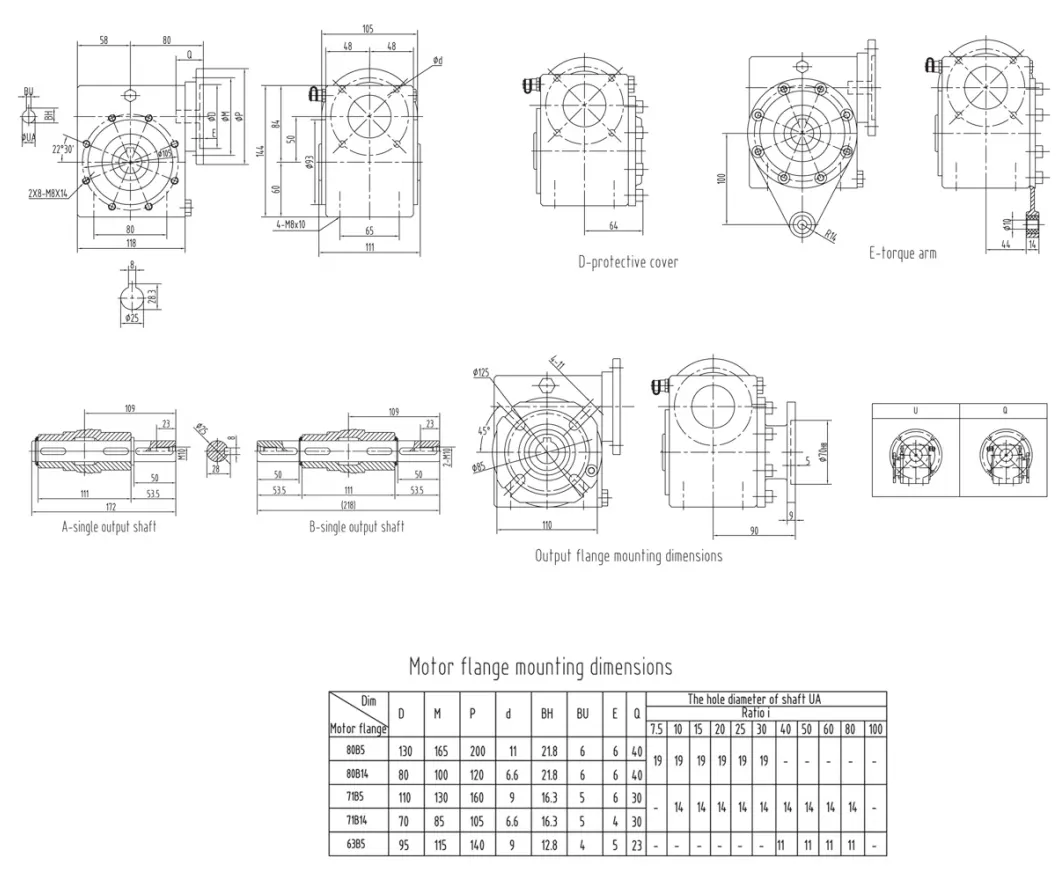

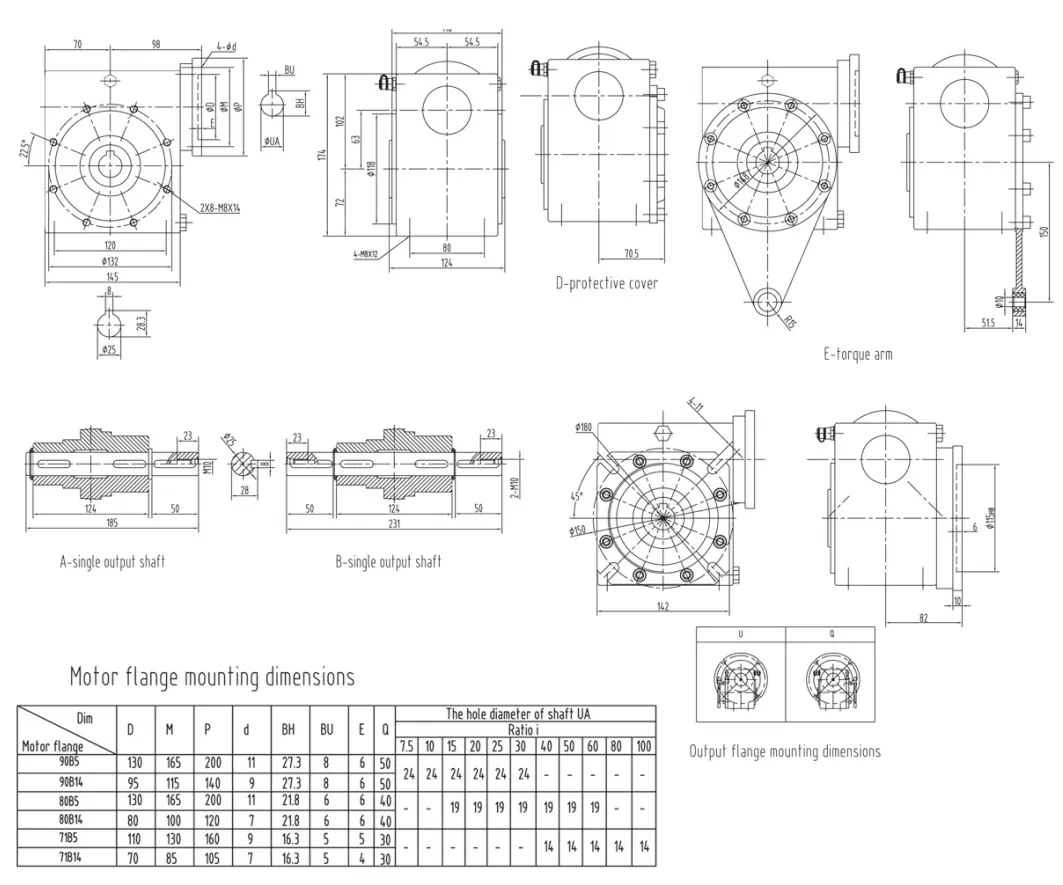

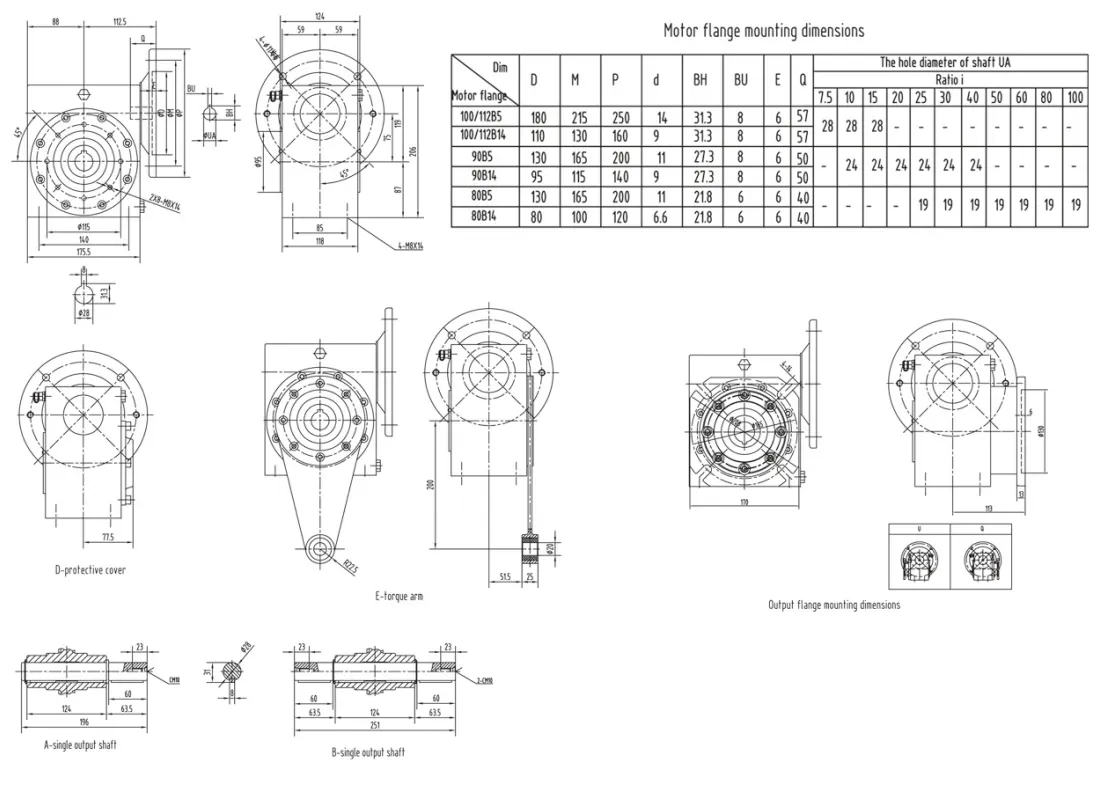

Mounting Dimensions

These images provide the installation dimensions for the EP-GMSS Series Stainless Steel Worm Gearbox:

EP-GMSS30

EP-GMSS40

EP-GMSS50

EP-GMSS63

EP-GMSS75

EP-GMSS90

التطبيقات

The EP-GMSS Series Stainless Steel Worm Gearbox finds its application in various industries and scenarios. The gearbox offers durability and reliability, making it suitable for demanding environments. Below are some of the industries and scenarios where this gearbox excels:

1. Food and Beverage Industry: The stainless steel construction of the gearbox ensures compliance with hygiene standards. It is ideal for applications involving food processing, bottling, and packaging.

2. Pharmaceutical Industry: The gearbox's corrosion-resistant properties make it suitable for pharmaceutical manufacturing processes, ensuring product integrity and purity.

3. Chemical Industry: With excellent resistance to chemical substances, this gearbox is well-suited for applications involving chemical production, where harsh environments are common.

4. Water Treatment: The gearbox's robust design allows it to handle the challenges of water treatment plants, including the handling of wastewater, sludge, and filtration systems.

5. Outdoor Applications: The gearbox's stainless steel construction makes it resistant to harsh weather conditions, making it suitable for outdoor applications such as agricultural machinery and outdoor installations.

6. Marine Industry: Due to its corrosion-resistant properties, this gearbox is ideal for marine applications such as ship propulsion systems and winches.

7. Mining and Construction: The gearbox's durability and ruggedness make it suitable for heavy-duty applications in mining and construction machinery, where reliability is crucial.

Overall, the EP-GMSS Series Stainless Steel Worm Gearbox offers a versatile solution for a wide range of industries and scenarios, providing reliable performance in demanding environments.

Characteristics of EP-GMSS Series Stainless Steel Worm Gearbox

- High-quality stainless steel material ensures excellent corrosion resistance, making it suitable for use in harsh environments.

- Compact design and small size make it easy to install and use in tight spaces.

- The worm gear transmission design provides high efficiency, low noise, and stable operation.

- Large transmission ratio range makes it easy to adjust the output speed of the gearbox to meet different application needs.

- The gear surface is precisely machined to ensure accurate tooth profile and smooth meshing, reducing wear and extending the service life of the gearbox.

In addition, the EP-GMSS Series Stainless Steel Worm Gearbox has a wide range of applications, including in the food, pharmaceutical, chemical, and other industries that require high hygiene and cleanliness standards. With its excellent performance and durability, this gearbox is an ideal choice for demanding applications that require high precision and reliability.

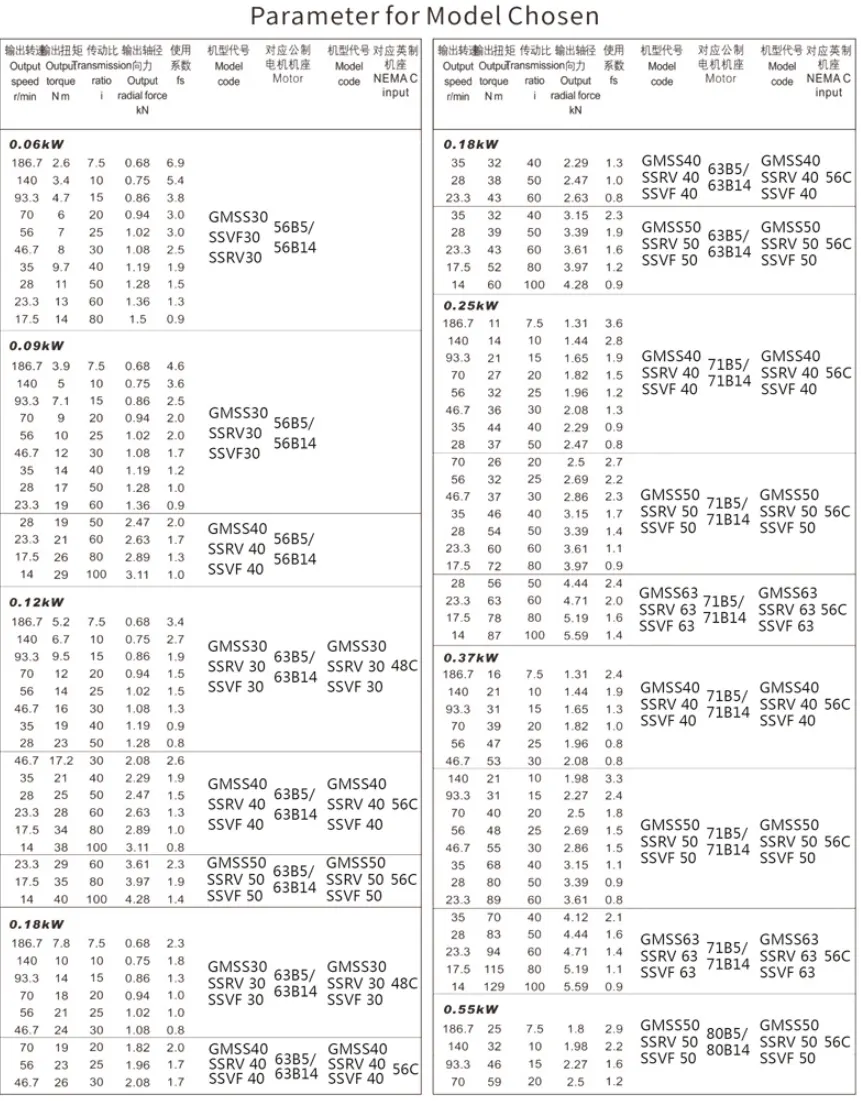

How to Choose a Suitable Stainless Steel Worm Gearbox

When it comes to selecting a suitable stainless steel worm gearbox, there are certain points that need to be taken into consideration. Here are some key factors to keep in mind:

- Operating Conditions: Consider the specific operating conditions such as speed, torque, and ambient temperature that the gearbox will be exposed to.

- Load Requirements: Determine the required load capacity and the maximum axial and radial load that the gearbox needs to withstand.

- Efficiency: Evaluate the efficiency of the gearbox, as it directly affects the power transmission and overall performance.

- Gear Ratio: Choose the appropriate gear ratio based on the desired speed reduction or increase.

- Noise and Vibration: Consider the level of noise and vibration tolerance required for your application.

- Sealing: Ensure that the gearbox has proper sealing to protect it from dust, moisture, and other environmental factors.

- Maintenance: Assess the ease of maintenance and the availability of spare parts for the chosen gearbox.

For more detailed information on the selection parameters of stainless steel worm gearboxes, please refer to the following parameter table:

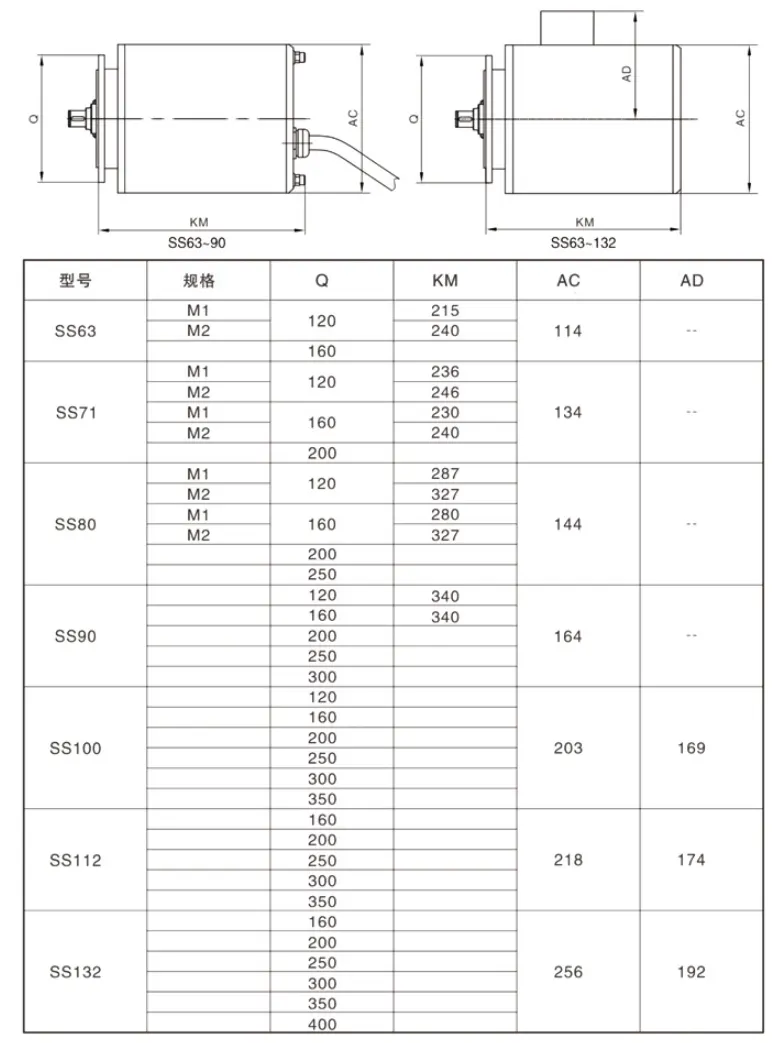

Stainless Steel Motors for EP-GMSS Series Worm Gearboxes

Looking for a complete solution for your harsh environment application? Look no further than Ever-Power's EP-GMSS Series Stainless Steel Worm Gearboxes and Stainless Steel Motors. Our motors are specifically designed to withstand the same harsh conditions as our gearboxes, with IP65 and IP66 ratings available.

Our stainless steel motors are available in a range of sizes to meet your application needs.

Stainless Steel Worm Gearboxes Manufacturer

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands. As the exclusive sales representative, we proudly offer the EP-GMSS Series Stainless Steel Worm Gearbox. Our products are known for their exceptional quality and service, delivering outstanding performance to our customers.

With a focus on precision engineering and durability, our stainless steel worm gearboxes are designed to withstand the harshest conditions and deliver reliable power transmission. They are resistant to corrosion, ensuring longevity and minimizing maintenance requirements. Our gearboxes are meticulously crafted to meet industry standards and exceed customer expectations.

In addition to stainless steel gearboxes, we also provide a wide range of other non-standard gearboxes for various applications. Whether you require a gearbox for an automatic car wash machine, a fountain, a snow blower, or any other specialized equipment, we have you covered. Our team of experts can customize gearboxes to meet your specific requirements.

At RP Techniek BV, we are committed to delivering superior products and exceptional customer service. Contact us today to learn more about our stainless steel worm gearboxes and explore our comprehensive range of gearbox solutions.

معلومات إضافية

| Editor | Zqq |

|---|

تم تحديث المدونات

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...